Innovate UK – Our work to INSPIRE

Sponsor: Innovate UK

By partnering with industry to develop and deliver collaborative programmes and by supporting world-leading institutions, such as the High Value Manufacturing Catapult, we seek to inspire innovative businesses to work collaboratively to solve key societal challenges.

£15m of the £54m total cost of the Glass Futures pilot facility has been covered by the Transforming Foundation Industries Challenge

Industrial Strategy Challenge Fund

The Industrial Strategy Challenge Fund is a major innovation programme led by UK Research and Innovation (UKRI). An investment of around £2.6bn of public money and £3bn in matched funding from the private sector has been focused on projects that bring together researchers

and businesses to tackle today’s big societal and industrial challenges. These include:

Made Smarter Innovation Challenge

This programme is focused on innovations in digital technology to help the UK boost productivity by up to 30% by 2030. The Challenge is a £147m government investment. Its aim is to transform UK manufacturing by delivering high tech products at pace and on price, thanks to digital innovation.

CASE STUDY: GKN Aerospace

GKN Aerospace is leading a cross-sector team, involving organisations from the aerospace, automotive and pharmaceutical industries, to trial a combination of digital technologies in live manufacturing environments.

These include artificial intelligence and machine learning technologies, intelligent robots and smart devices that can exchange information between old and modern computer systems, allowing a greater understanding of data. The ongoing project will create a more seamless flow of real-time information, enabling cost-effective manufacturing decisions across the supply chain.

Transforming Foundation Industries Challenge

This challenge is supporting innovation and jobs by seeking to boost sustainability and international competitiveness in foundation industries. The challenge has up to £66m to invest in direct projects, match funded by £83m from the private sector to ensure improvements to energy and resource efficiency.

Glass Futures Pilot facility

A new pilot facility in St Helens will provide a centre of excellence for the sustainable manufacture of glass. The Challenge has contributed £15m of the £54m total cost of the construction of a new Glass Futures pilot facility. Due to open in 2023, the facility will be set up in St Helens to accelerate the development of promising clean technologies. Other contributing partners are Liverpool City Region Combined Authority and St Helens District Council, with an additional £20m industry contribution.

The 30 tonnes per day furnace and associated processing equipment will enable members from the glass and other high-temperature sectors to undertake process improvement experiments at a highly instrumented pilot site.

The facility in St Helens is on a former glassworks site historically occupied by United Glass. Business secretary, Kwasi Kwarteng, says; “This new funding will build on our commitment to cut emissions across heavy industry, create green-collar jobs on Merseyside and help us to build back greener.”

Smart Sustainable Plastic Packaging Challenge

£60m of funding to position the UK at the forefront of next-generation sustainable plastic packaging systems.

CASE STUDY: Flexi-Hex

Flexi-Hex is on a mission to make sustainability viable through an innovative and thoughtfully designed packaging solution: the Flexi-Hex® sleeve – a patented honeycomb design made from paper that helps protect products and the planet.

Made from more than 85% recycled paper pulp, the innovative hexagonal cell structure is strong, adaptable and provides reliable protection for a wide range of fragile products including bottles, boardsports, cosmetics, electronics, homeware and commercial.

This carbon-neutral company is already creating an impact having removed more than 3,100km of plastic from the packaging industry. As a certified B Corp™, Flexi-Hex is committed to improving its impact and questioning how its business

can become as regenerative as possible.

Plastics Research and Innovation Fund

An investment partnership between Innovate UK and Sky Ocean Ventures to support UK companies working on original ways to reduce waste, pollution and the devastating flow of plastics into oceans around the world.

The High Value Manufacturing Catapult

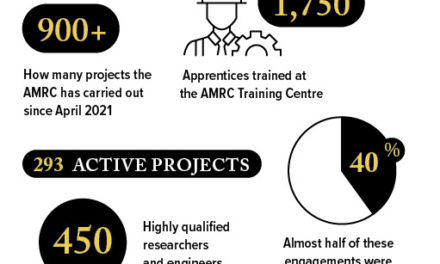

HVM Catapult accelerates new concepts to commercial reality through seven high performing centres of industrial innovation. It is sponsored by Innovate UK and is the go-to place for advanced manufacturing technologies in the UK.

Bridging the gap between business and academia it offers access to some of the best research and development facilities and expertise that would otherwise be out of reach for many UK businesses. Seven centres operate across

18 sites to enable economic growth and societal and environmental progress.

The Compound Semiconductor Applications Catapult

The CSA Catapult develops applications technology that outperforms silicon chips in speed, power and light to save energy and reduce emissions. It is also sponsored by Innovate UK and based in Newport, Wales.

The CSA Catapult plays a key role in the world’s first compound semiconductor cluster, a cumulative

strategic investment of more than £600m. Compound semiconductors are integral to achieving the UK government’s 2050 net zero targets and ensuring secure and resilient communications in the digital world.

The CSA Catapult collaborates with large companies, start-ups and universities to develop and commercialise new compound semiconductor applications. Its technology expertise covers photonics, power electronics, radio frequency and microwave, and advanced packaging.