Welcome to the 5G factory of the future

Sponsor: The University of Sheffield AMRC

A ground-breaking project is demonstrating new and more efficient ways of manufacturing to lead industry towards a smart, sustainable and resilient future.

The next-generation connectivity delivered by 5G technology – faster speeds, lower latency, larger bandwidth and greater security – has the power to unlock the true potential of industrial digitalisation and make ‘smart factories’ the norm.

The 5G Factory of the Future open-access industrial testbed is accelerating the pace of change and helping industry to better understand the place and benefits of 5G, and stimulating the adoption of 5G within manufacturing.

The vision is to dramatically improve manufacturer performance through the use of key digital technologies such as internet of things (IoT), mobile edge computing, visual inspection, artificial intelligence (AI), machine learning (ML), virtual and augmented reality (V/AR) and digital twins. All underpinned by 5G connectivity.

In doing so, the testbed will validate new ways of working that help UK manufacturers of all sizes to de-risk innovation and improve efficiency, productivity and safety, while reducing CO2 emissions and other waste.

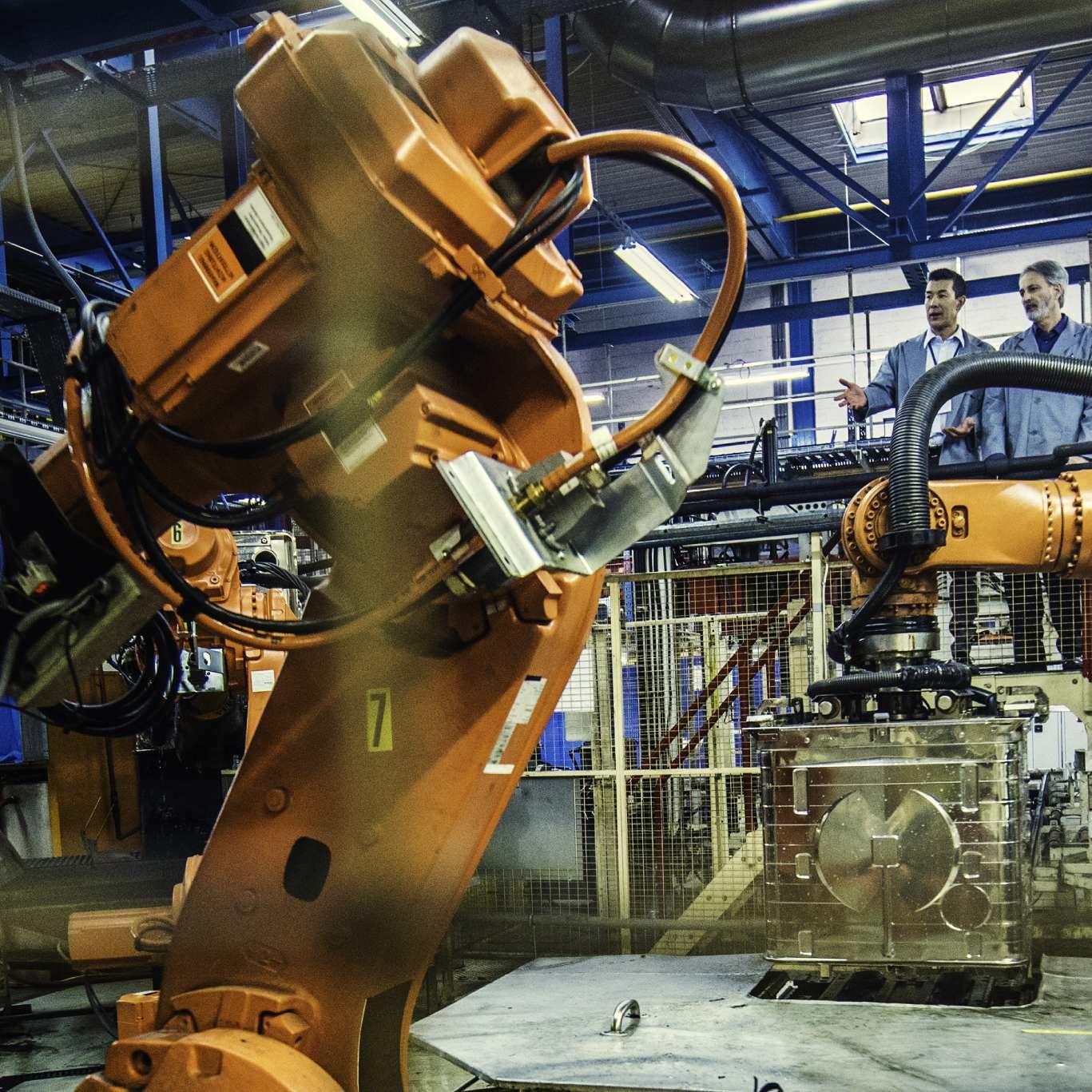

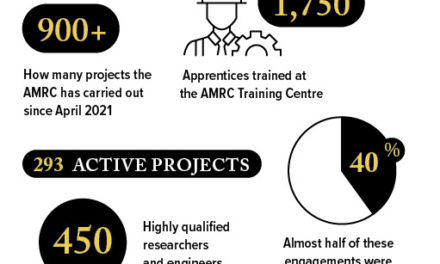

Led by the University of Sheffield Advanced Manufacturing Research Centre (AMRC) North West, the project consortium includes BAE Systems, IBM, telecoms provider aql, Machine Tool Technologies (MTT) and data-driven logistics specialist Miralis. Digital Catapult is the technical authority lead and integration and ecosystem coordinator.

The testbed is based primarily at the AMRC’s newly opened £20m North West facility in Lancashire, along with a significant footprint at BAE Systems’ site in Warton and the AMRC’s Factory 2050 facility in Sheffield.

Five industrial uses cases across the three sites are helping test the most challenging and ground-breaking areas of 5G for manufacturing to create a blueprint for smart factory connectivity. In almost every application, all data will flow through a 5G network to understand the benefits and constraints of 5G on manufacturing processes.

Learn more at www.5gfof.co.uk

1. Real-time Monitoring and Adaptive Closed-Loop Control

Challenge: Reduce cost and time associated with defects and quality issues; create a no-fault forward manufacturing system.

This application is using the decreased latency capabilities of 5G to monitor high-frequency, high-throughput machining and manufacturing processes. IoT data generated from sensors placed on machines is helping to improve quality, insight and efficiencies.

Result: Estimated 15%-25% reduction in the number of defects, amount of waste generated and machine downtime arising from improved process precision and predictive maintenance strategies and fewer errors.

2. Digital Twin Track and Trace

Challenge: Investigate floor space optimisation and costs; remote maintenance and operations; training and learning; and using virtual technology to test ideas that if done physically can be time-consuming, costly and disruptive

A digital twin is a dynamic virtual representation of a physical object or system, usually across multiple stages of its lifecycle. It can be used to answer ‘what-if’ questions and present insights in an intuitive way by using real-world data, simulation and/or machine learning models, combined with data analysis, to enable understanding, learning and reasoning.

Where other industrial use cases utilise specific machines, technology and processes, this application supports those use cases to enhance their capabilities and apply digital twin principles.

Result: Estimated 15-20% machine utilisation improvement and factory efficiency, arising from data-driven decision-making, real-time asset location and inventory accuracy, efficient scheduling, asset performance optimisation and improved predictive maintenance.

3. Factory Ecosystem Monitoring

Challenge: Reduce infrastructure and through-life operational costs via real-time, agile monitoring of critical production environments.

This application uses sensor data and 5G to capture, monitor and gain insight of the changing variable conditions within a factory environment. Ultimately, this data will benefit operations by adjusting activities and settings to compensate for any changes in the environment.

It also provides insight into how external influences and local environmental conditions can affect operations and cause fluctuations in tolerances.

Result: Estimated 5-10% improved machine utilisation and 10-20% reduction in energy use and maintenance time, arising from performance optimisation and enhanced resource utilisation.

4. Distributed and Shared Hybrid Reality Spaces

Challenge: Enabling real-time rich information and AI assistance to be exploited by people at the point of use; reducing the cost of downtime, interpretation and uncertainty.

This use case investigates the use of augmented and mixed reality technologies for assembly, maintenance and inspection activities, for example manufacturing instructions. The digital instructions are fed directly to a worker at the point of use via devices such as wireless hand-held tablets and personal headsets.

It integrates digital work instructions with CAD designs to help engineers carry out production and maintenance activities. Low latency instructions, enabled by 5G technology, could save about five seconds per instruction read compared with traditional methods.

In addition to AR, this application will also investigate the review and approval of CAD designs by testing the use of visual inspection to validate a process, such as the positioning of labels and the parts they attach to, for example.

Result: Estimated 65% reduction in travel costs and 15% in maintenance time arising from real-time, worldwide collaboration and increased ease of training and maintenance support.

5. Chain of Custody System

Challenge: Increase visibility across the supply chain through all tiers for assets and products, guaranteeing operational efficiency and delivery to customers.

This application is using 5G to track and observe asset conditions in transit, ensuring the product is within acceptable standards when it arrives. Assets – in this instance, a tool or part – will have sensors attached or be carried in smart containers or boxes that have sensors and connections to 5G.

The sensors provide feedback on asset conditions which could be environmental such as temperature, events such as shock or exposure to extremes, or location using GPS. The data can then be utilised to better track the location of assets and respond to events that take them outside tolerances.

Result: Estimated 30% reduction in lost and damaged assets and improved schedule accuracy, alongside providing supply chain transparency and real-time condition monitoring for assets tracked by the system.