Naylor Industries

Above: Naylor Concrete Products, manufacturers of fencing and lintels, among other construction necessities. The company made capital investments worth £5.7m during the past financial year

Naylor Industries is a fourth-generation family business based in Barnsley, South Yorkshire, which manufactures products out of clay, plastic and concrete.

The company was founded as a clay sewer pipe manufacturer in 1890, and still continues to predominantly supply the construction industry. but recent years have seen Naylor diversify and launch new products. The company now has seven sites- four in Yorkshire, and one each in Fife, Gainsborough and the West Midlands, and more than 400 employees.

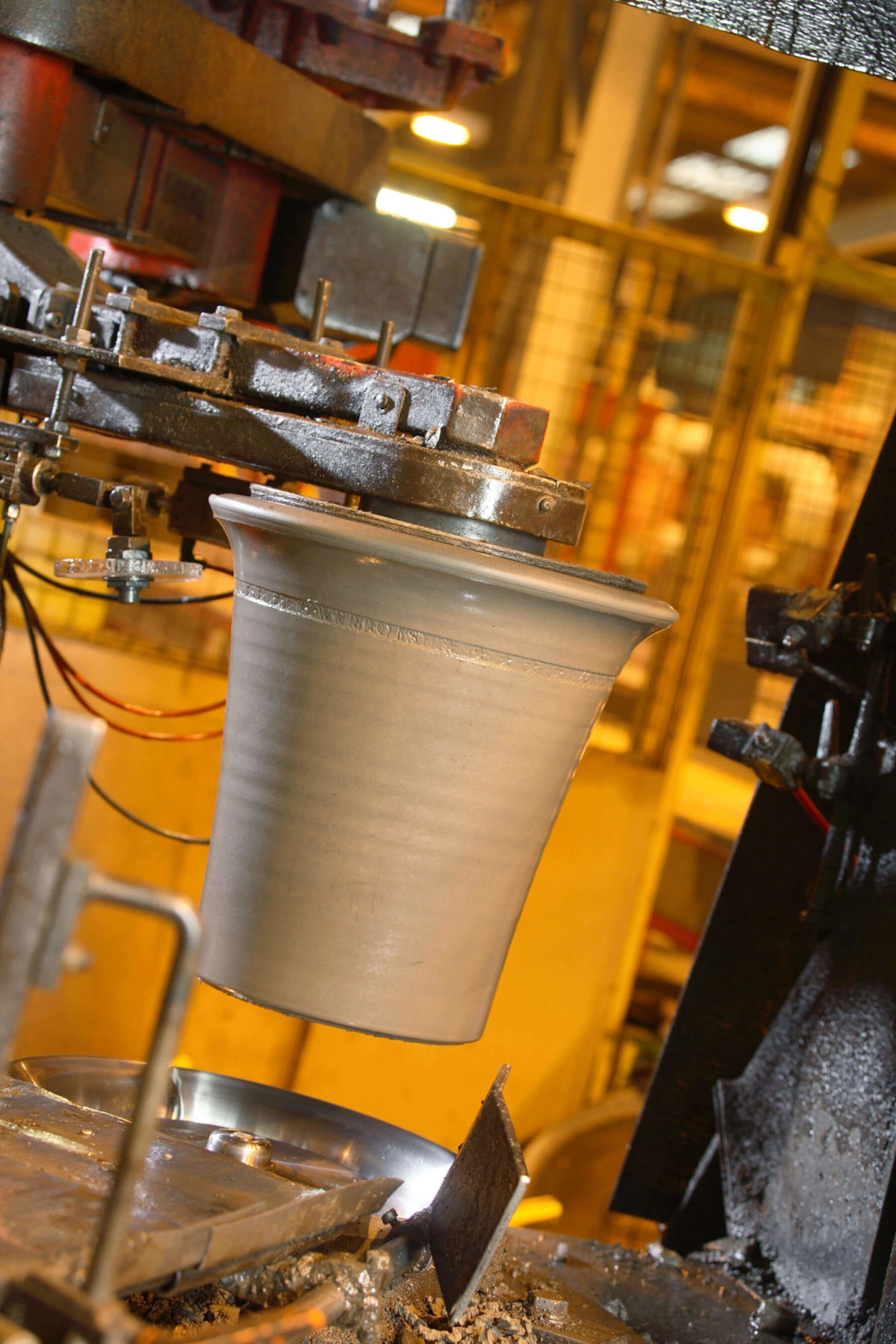

Naylor’s largest business, Naylor Drainage, still manufactures clay pipes most recently developing specialised ranges including Denlok, a super-strength clay jacking pipe, which can be pushed through the ground, thereby avoiding the disruption associated with conventional pipe installation. The significant export business associated with this product resulted in the company receiving a Queen’s Award for International Trade in 2022.

An even more unlikely diversification is the company’s development of its Yorkshire Flowerpot business – now Britain’s largest manufacturer of terracotta gardenware, which manufactures around 250,000 pots every year. Meanwhile the company has also developed a major presence in the Plastic Pipe market becoming a major manufacturer of pipes for the surface water, agricultural and cable ducting sectors.

Naylor’s other businesses include Naylor Concrete Products, which manufactures concrete lintels, fencing and other prestressed products, and Naylor Specialist Plastics, which manufactures plastic tubes and profiles for a wide range of industrial sectors and clients.

Naylor’s 2021-22 financial year reported £70m turnover – 36% up on the previous year; the company continued its aggressive capital investment programme, making £5.7m

of capital investments during the

year, adding new equipment across all its sites.

Naylor is large enough to have good infrastructure and worldwide geographic reach but tight-knit enough to be flexible and responsive to customers’ needs for bespoke products or services. Decision making is quick and Naylor’s people and systems are flexible. CEO Edward Naylor tells us more about the firm and what sets it apart from the competition; “We aim to offer a much more personal service than our large corporate competitors. Our customers deal with named internal contacts, not anonymous call centres; many of our customer relationships go back decades.”

Recycled polyethylene used in plastic pipes

Naylor’s use of plastics has however not harmed its green credentials: the company uses secondary (recycled) materials wherever possible and last year used some 7,000 tonnes of recycled Polyethylene (PE), the source of much of this being recycled milk packaging. Equally, product design is important to the footprint of Naylor’s Plastic business; production mainly comprises structured “Twin” wall pipe, a product design which achieves maximum strength with minimum material content.