Northern Ireland – An economic vision to take Northern Ireland’s industry to the next level

Above l-r: James Norris, MD of J N Hire; Joe Annett, Founder and MD of Anachem Hygiene; Invest Northern Ireland’s Mark Bleakney, and Ronald McConnell, Partner, Mourne Craft.

Regions: Northern Ireland

Northern Irish manufacturers are managing to grow and innovate despite having to navigate strong headwinds in the form of Brexit, rising costs and a shortage of skilled labour.

Above: With around 75% of its countryside being farmed in some way, it’s unsurprising that food and drink is the region’s largest manufacturing industry. Credit: Leonid Andronov | Stock.adobe.com

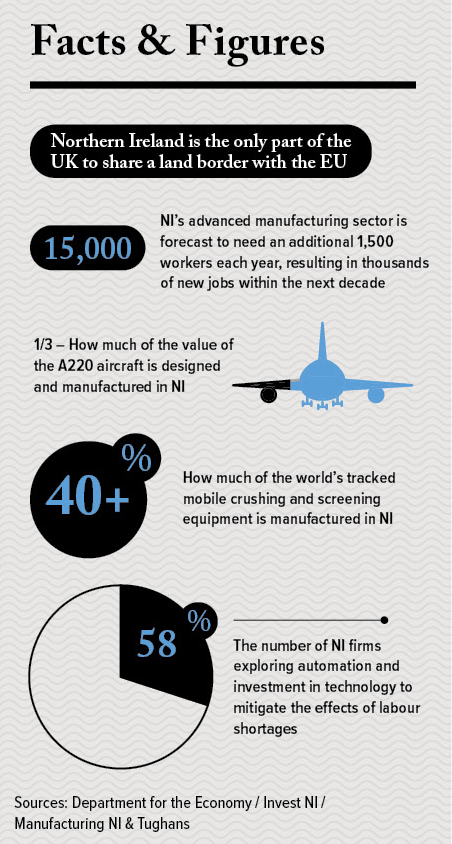

Northern Ireland may be the UK’s smallest region in terms of gross value add but it has a vibrant and highly sophisticated advanced manufacturing, materials and engineering sector. There’s a reason why the likes of Airbus, Boeing, Embraer, BAE Systems, Spirit AeroSystems, GKN Aerospace and Thales, among many others, have established strong links with the region (and that’s just from aerospace and defence).

The region’s manufacturing strength is a result of its rich, diverse industrial heritage combined with modern digital technologies. At one time, Belfast had the largest shipyard and rope works in the world, and its importance to global linen production earned it the moniker ‘Linenopolis’.

Today, Northern Ireland is an established international player in sectors spanning aerospace, defence and space, transport, life and health sciences, construction, electronics and renewable energy. These capabilities are complemented by its status as a globally-recognised tech hub, with a particularly strong presence in cybersecurity and AI. Ideal for those looking to utilise their factory data more quickly, efficiently and securely.

This combination of traditional skills and experience with digital innovation helps support every stage of manufacturing, from R&D through new product development to production and export. Indeed, the manufacturing sector accounts for almost 60% of exports.

Increasing export demand

The obvious fly in the ointment is Brexit. The latest State of Manufacturing NI report from Manufacturing NI and Tughans, published in April 2022, reveals that “GB suppliers’ unpreparedness and unwillingness to adopt the new Brexit regulations remains a significant barrier to trading”.

Yet, more than half of Northern Ireland’s manufacturing businesses are experiencing growth so far this year. Further positivity comes via the markedly fewer companies describing their business as reducing or contracting compared to April 2021 (11% and 17%, respectively).

The findings also reveal that despite very difficult headwinds from rapidly soaring input costs and the complications of Covid and Brexit, Northern Ireland’s manufacturers are increasingly picking up new export business. More than a third of businesses anticipate increased export sales to EU markets, and one in four expect the same in the UK.

All this, in spite of “current minimum public assistance,” notes Manufacturing NI chief, Stephen Kelly. Though work is currently underway to address the disparity.

Prioritising STEM subjects

In May 2021, the Department for the Economy (Northern Ireland) unveiled its 10X Economy vision outlining what the region could achieve over the next decade. The intention is to deliver “a 10-times better economy” by focusing on innovation in areas where Northern Ireland already has or could have a global strength. Manufacturing is an obvious choice and rightly included as one of the vision’s five ‘priority clusters’.

The Department notes that; “Success in these areas will bring momentum that can spread to all parts of our economy and create opportunities for people across our society.” This sounds very similar to the UK government’s recent ‘Levelling Up’ plan, although Northern Ireland arguably places a more explicit emphasis on industry.

However, also like the UK, Northern Ireland’s growth ambitions could be curtailed by a lack of skills. The undersupply in many of the STEM subjects is a long-standing challenge that will only become more acute as manufacturers, and other sectors, continue to drive demand for qualifications in computer science and engineering subjects.

Recognising that skills are a key pillar for future growth, the Department for the Economy published its Skills Strategy for the 10X Economy in March 2022 – its first such strategy in more than a decade. As you would expect, there is a strong emphasis on increasing further education qualifications in technical and professional skills and rebalancing higher education towards science, technology, engineering and maths (STEM).

Realising those goals requires substantial investment. The paper states that investment in education and skills “declined substantially” during the 2010s and to return education and skills in ‘real terms’ to 2010-11 levels of expenditure would require an additional £429m a year.

Where this additional investment will come from is currently unknown. The paper mentions that policy decisions on tuition fees have “limited the capacity of universities to raise revenue, leaving per capita student funding behind other UK regions”. Yet, it also notes that government investment in education and skills has increased as part of the post-pandemic economic recovery efforts.

In the meantime, almost two-thirds of manufacturing businesses are exploring automation and investment in technology to mitigate the effects of labour shortages, according to the latest State of Manufacturing NI report. l

News in Brief

- Three Kilkeel-based manufacturing SMEs are investing more than £650,000 to grow their businesses and collectively create 12 new jobs. Mourne Craft specialises in the design, manufacture and installation of external stainless steel and glass balustrades and internal staircases for commercial and residential projects. Anachem Hygiene has been developing and manufacturing cleaning chemicals for professional, industrial and automotive sectors from its Kilkeel facility for more than 20 years. Plant hire company J N Hire recently began manufacturing hydraulics and specialist PPE for the fishing and marine sectors, which has boosted its exporting potential.

- South Africa’s Moorcroft Foods has announced it’s establishing a manufacturing facility in Newtownards, which will see the creation of 11 jobs. The company will manufacture and sell Biltong and Droewors, both dried meat products, from its new premises and aims to take advantage of ‘food to go and snacking’ opportunities in Great Britain, Republic of Ireland and Europe.

- Queen’s University Belfast and NVIDIA are investing £5.4m in a joint R&D project with the aim to accelerate artificial intelligence, machine learning and cybersecurity research in Northern Ireland. NVIDIA’s Belfast office will become a research hub for advanced network intelligence, with 10 new, highly skilled engineering and research roles being created. The graphics processing giant intends to work closely with researchers and PhDs at the university, as well as its labs at the Centre for Secure Information Technologies and the Global Innovation Institute.

- Precision medicine company, Almac Group has made a £500,000 investment in nuclear magnetic resonance (NMR) instrumentation at its global headquarters in Craigavon, taking its total investment in NMR technology to £900,000 since 2018. The addition of a second 500MHz NMR system will further expand its current service offering, while also increasing throughput, capacity, and speed to enhance efficiency and turnaround times.

- Specialist paving and building products company, AG, has reduced its Scope 1 and 2 emissions by 10%, despite a 30% increase in production volumes. The business, which has manufacturing locations in Fivemiletown, Dungannon, Toome, Ballygawley and Carryduff, previously switched to 100% renewable energy as well as utilising bio-LPG resulting in a carbon saving of 70%. The business has also introduced electric and hybrid cars into its fleet with a goal of having a full hybrid/electric fleet by 2025.

- Ryobi Aluminium Casting UK, winner of ‘Best Large Company of the Year’ and ‘Outstanding Business of the Year’ at Belfast Telegraph Business Awards 2021, has recently installed a new 20-tonne, £500,000 CNC machining centre. Further investments are expected to be made in new robotics, conveyors, washers and automation systems.

- Ardagh Metal Packaging (AMP) is moving forward with plans to build its new £150m beverage can plant near Belfast. The plant will be located near Belfast and will service the growing needs of beverage customers in Ireland, the UK and Europe. Though details on precise job numbers are still being finalised, the investment is expected to create a large number of full-time jobs for engineers, technicians and other roles. Recruitment is expected to begin this year ahead of the plant coming online in 2023.

- Octopus Energy Group has made a multimillion-pound strategic investment to

take a controlling stake in heat pump manufacturer Renewable Energy Devices. The investment will see a significant expansion of RED’s existing factory in Craigavon to produce more than 1,000 heat pumps a month by the end of 2022.

Below: Octopus Energy has also recently invested in the UK’s first heat pump R&D and training centre. The move is expected to create 100 new green engineering jobs by 2024 and the partners are also in the process of scoping other locations to build further heat pump manufacturing facilities.

Below: These technologies will shape the future, and Northern Ireland has established real strength in a selection of them. When brought together to form ‘clusters’, these technologies can generate increased innovation, higher levels of competitiveness and help businesses diversify into new markets.