Wales – Optimism born from adversity

Regions: Wales

Above: Aston Martin St Athan

Welsh manufacturers have been eyeing a potential light at the end of the tunnel for more than three years now. In the meantime, they have learned to adapt and innovate.

Above: An Airbus engineer manufacturers a component of the Penlon ventilator at AMRC Cymru. Credit: AMRC Cymru

The confidence of manufacturers in Wales waned through the second half of 2021 and stuttered moving into 2022 on the back of an apparent false dawn post-Covid and a growing list of concerns.

Brexit (still), skills shortages, soaring prices (materials and energy) and the war in Ukraine top a longer list. However, companies on the ground exude a perhaps surprising optimism born out of a new-found ability to pivot in response to adversity.

Alison Orrells, CEO and managing director of The Safety Letterbox Company, a Neath-based manufacturer and designer of mail and parcel boxes, describes the current set of challenges as “the perfect storm”. But she too conveys a pragmatic willingness to innovate, initially grasped by many through the challenges of Covid.

“We are dealing with significant material price increases, carriage costs and logistics impacts, additional export admin from Brexit, skills shortages, the continued impact of Covid and now soaring energy prices,” she says, adding that customers also want products cheaper than ever before.

She explains; “The added value, service and quality required has meant we have also continued to grow and reinvest. Investment in CSR and brand positioning have been vital in such difficult markets. We have expanded into new offices, harnessed a collaborative and driven sales culture, lost working remotely, invested further in R&D, new machinery and new products – all while also focusing on employees’ wellbeing and mental health.”

Manufacturing Wales

Born out of the challenges facing Welsh manufacturers and a desire to leverage any advantage in such a competitive world, a new representative body for the sector in Wales was established in 2021.

Launched alongside the Made in Wales brand, Manufacturing Wales was conceived and created organically by eight founder members, one of which was The Safety Letterbox Company. It describes itself as a collaborate community created by the industry for the industry and ‘a new independent voice for manufacturing in Wales’.

Heather Anstey-Myers, the first CEO of Manufacturing Wales, echoes the views of Orrells on the challenges the sector is facing. “The field of play for manufacturing is complex. The sector has to balance supply chain resilience, fluctuating materials costs, decarbonisation, logistical uncertainty, digitisation and automation – all while finding the right talent,” she says.

But she too highlights the many positives and believes Manufacturing Wales, combined with support schemes delivered by the Welsh Government, can help the sector tackle many of these issues and also raise the credibility of Welsh brands, maximising supply chain opportunities, sharing best practice and deliver events that develop foresight for the sector.

“Welsh manufacturing is well placed to face its challenges,” she says. “The investment in clusters of excellence; the advanced manufacturing capabilities that are already in Wales; the many projects coming forward through the growth deals and the private sector location of key facilities, along with the connection to global opportunities working with partners such as Global Welsh, all have a great potential to significantly boost the sector.

“There are also strong support frameworks in Wales too, whether this be to develop the skills, R&D, innovation or investment – all of which help futureproof the sector. Welsh manufacturing has been proven to be world class. Every manufacturer should be proud to bear the Made in Wales brand because it represents quality,

and this stands the sector in great stead for

the future.”

Hard numbers

A close look at some statistics indicate the journey Welsh manufacturers have been on in the past few years. The 2021 Regional Manufacturing Outlook by Make UK notes the “peaks and troughs” manufacturers have experienced in the past year.

For Wales, where the manufacturing sector contributes less than 1% of the UK’s total output, confidence indicators spanning the 12-month period Q3 2019 to Q2 2021, show manufacturers in almost bullish mood by mid-way 2021.

At that point a UK-wide manufacturing recovery was underway, but, in Wales specifically, confidence by Q2 2021 had increased to 6.7 (on a scale of 1-10) compared with just 5.9 at the start of that period.

It appears this was largely on the back of bullish order books, up eight percentage points in that period, and despite falls in output, investment and employment (down six, five and eight percentage points, respectively). In real terms, the report estimates the Welsh manufacturing sector had lost 6,000 jobs in the two-years prior.

“Wales has posted moderately negative results for its year average performance across key metrics. The exception to this is that of orders performance, which has managed to remain just positive over the past four quarters’ average.

“While the wider UK enjoyed a very performant second quarter of 2021, Wales reported a no-change result for the quarter, which in turn has fed the expectation that the Welsh manufacturing recovery over the rest of the year will be at a slower pace than that of the wider UK industry,” the report states.

Yet spin forward nine months and the confidence of Welsh manufacturers was waning. The Make UK Regional Manufacturing Outlook 2022 Q1, shows that business confidence had dropped to 6.2 and employment, output and investment were all falling. Across the UK, in fact, manufacturing activity strengthened by February 2022, but this was against the spectre of expected price rises and the war in Ukraine.

A time for reinvention

Commenting on the CBI’s monthly Industrial Trends Survey for February 2022, Ian Price, CBI Wales director, said: “While UK growth overall was steady in the quarter to February, it’s encouraging that some sectors saw a faster pick-up in activity – most notably manufacturing and consumer services.

“The strengthening in expectations likely reflected fading Omicron concerns at the time, and final Covid restrictions being lifted across the whole of the UK. In Wales, that likely meant some of the hardest-hit businesses, particularly those in the hospitality, leisure and tourism sectors, benefitting from an uptick in mobility and confidence.

“However, the conflict in Ukraine has cast a shadow over business confidence. The subsequent rise in global commodity prices and supply chain pressures will have an impact across the economy, at a time when businesses are already grappling with significant challenges, such as raw material shortages and other rising costs.”

Such challenges may well see Welsh manufacturers again lean on their ability to reinvent themselves, as so many were forced to due during Covid.

Pivot point

One company that exemplified the ability to pivot to endure challenging times was Ministry of Furniture, the company which emerged from Remploy Furniture.

Ministry, which normally designs, makes and upcycles cutting-edge furniture and graphics for offices and the education sector, repurposed its manufacturing facilities during the pandemic to make disposable face shields to help frontline key workers. It also developed the ability to make polycarbonate screens that were used as protective barriers in hospitals and also helped many businesses reopen safely as restrictions eased.

Another example of this ability to innovate can be seen at timber frame construction specialist SO Modular, which has taken energy efficiency to a new level in its most recent development. The company has enjoyed strong growth in recent years following its statement of intent in 2020, when it spent £6.5m buying and regenerating the iconic Metal Box Factory in Neath – a bet on the future direction of housing construction in the UK. It basically makes houses indoors before constructing them onsite.

But at its recent development of 17 new low-carbon homes near Chepstow, it has shown new levels of innovation. They were constructed using a closed panel timber frame system, which uses Welsh sheep’s wool as insulation. Add in solar panels and ground-source heat pumps and the very energy efficient homes achieved a Standard Assessment Procedure (SAP) in excess of 100.

For others, it may be a case of turning their attention overseas. Wales is a competent exporter – in 2020 it was responsible for 5% of the UK’s total goods exports and it had the highest percentage of any UK region of goods travelling to the EU. Buoyed by the creation of Manufacturing Wales, more firms could seek export as a route to growth.

“The export interest is growing and it is an area of exploration albeit, it can be time consuming and challenging. But, from experience, it can also be rewarding and important for the international profile and interest in Welsh manufacturing,” Alison Orrells says.

News in Brief

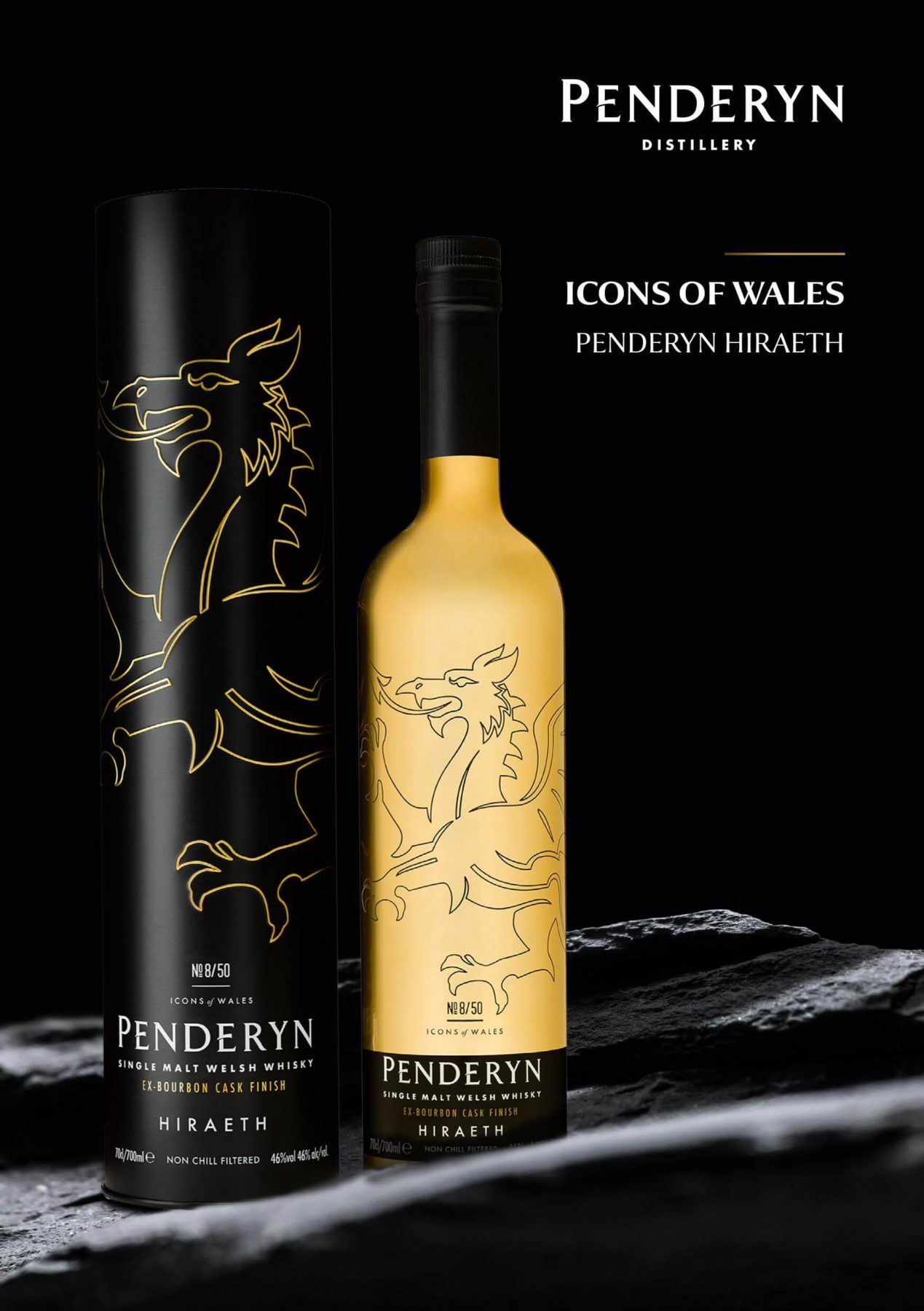

- Penderyn Distillery recently celebrated its 21st birthday with the opening of a new distillery in Llandudno. Plans are underway for a third distillery in Swansea on an old historic Copperworks site, which is intended to become a visitor attraction.

- Aston Martin is gearing up to take on more than 100 new skilled automotive technicians at its St Athan site in Wales, following the 2022 launch of its new DBX707 SUV model – the first Welsh-built production car for nearly 50 years.

- A £3.5m grant from the Aerospace Technology Institute (ATI) has allowed the University of Sheffield Advanced Manufacturing Research Centre (AMRC) Cymru to establish a Manufacturing Data Centre of Excellence in Broughton. The centre is tipped to deliver digital innovations that connect supply chains, increase productivity, drive sustainability and create high-value engineering jobs.

- A new factory in Rhyl making wooden frames for zero carbon modular homes is aiming to top £3m in sales in its first year. Supported by a £1m investment from Creating Enterprise, the social enterprise, a subsidiary of housing association Cartrefi Conwy, is also aiming to hire unemployed workers.

- Life sciences company Cytiva is opening a new manufacturing facility in Cardiff, creating 250 jobs. The site, part of a two-year £1.1bn global expansion plan, has begun to make mixer bags, flow kits and tubing assemblies used in the development and production of biopharmaceuticals such as Covid vaccines.

- Tywyn-based refrigeration technology company, Sure Chill, has created an innovative water-powered fridge that can be used to cool vaccines in third world countries.

“ Every manufacturer should be proud to bear the Made in Wales brand because it represents quality”

Above: Alison Orrells, CEO, The Safety Letterbox Company. Credit: Adrian White Photography

Above: Heather, Anstey-Myers, CEO, Manufacturing Wales. Credit: Manufacturing Wales

Above: Ministry of Furniture repurposed its manufacturing facilities during the pandemic to make polycarbonate screens. Below: An example of Ministry of Furniture’s normal work making furniture and graphics. Both credit: Ministry of Furniture

Below: Penderyn Distillery opened a new distillery in Llandudno in May 2021.

Below: The distillery has also launched a bottle of whisky called Hiraeth, which celebrates a longing for Wales.