Success is getting harder to hide in East Midlands

Regions East Midlands

Above: Catesby Tunnel houses a 2.7km long, purpose-built straight road test track allowing an extensive range of assessment studies to be carried out on full-scale vehicles. Credit: Catesby Tunnel / TotalSim Ltd

Manufacturing investments in the East Midlands are accelerating. Formula 1 is in pole position currently but a raft of opportunities in established and emerging markets mean future growth is almost guaranteed.

Charles Orton-Jones

Above: Otmar Szafnauer, Aston Martin Cognizant CEO and Team Principal, JCB Chairman Lord Bamford, and Aston Martin Executive Chairman Lawrence Stroll. Credit: JCB

A curiosity of the East Midlands is how the gems of manufacturing are hidden away in villages and towns. The unwary traveller can wander past centres of industry totally oblivious. The village of Brixworth in Northamptonshire, for example, may be renowned for its ancient Saxon church but it is also home to Mercedes AMG, maker of engines for nine championship winning Formula 1 teams.

Close by is Ilmor Engineering, known for designing and producing world-championship race engines, as well as launchers and engines for unmanned aerial vehicles (UAVs). There is speculation the boom in demand for drones following the war in Ukraine will keep Ilmor’s production lines busy.

In a nutshell, Brixworth is a charming historic village with an advanced manufacturing industry attached. Thirty miles away is the village of Gaydon, home to the iconic Aston Martin. Drive through the village and you may catch sight of an engineer quickly wheeling engines across the main road to the other half of the site.

The latest Aston Martin development will raise the visual profile, a £200m, three-unit factory is being constructed on land across the road from the historic Silverstone Grand Prix Circuit. One building will house the team’s design and manufacturing resource, a second will house a brand-new wind tunnel and simulator, and the third will redevelop and repurpose the existing factory premises as a central hub with staff amenities and a logistics centre.

Behind closed doors

Some of the best sites are literally hidden. Near the village of Catesby, an ambitious project has converted an old Victorian railway tunnel into a one-of-a-kind wind tunnel and performance facility. The 2.7km tunnel offers testing of aerodynamics, speed, acceleration, braking and ride comfort including aeroacoustics, and engine emissions.

The surface is super-smooth, achieved by using specialist aggregate with a polished stone value (PSV) of 65. The tunnel will test everything from supercars and race vehicles to HGVs and bicycles, helping manufacturers across the region.

A short hop away is the town of Kettering, soon to be home to the largest and most modern oat-processing plant in Europe. The multimillion-pound facility will be screened by 6,500 new trees and shrubs to blend in with the rural landscape. The development is the initiative of Navara Oat Milling, a new joint venture between three large enterprises in the grain sector.

“The joint venture is launching at a time when the importance of nutritious, plant-based ingredients has become more widely recognised. Provenance and sustainability are part of that agenda, and domestically grown and processed oats are part of the answer,” explains George Thompson, group finance director of food and drink ingredient manufacturer AMH.

At the nearby SEGRO Park Kettering Gateway, work is underway on the largest aluminium can manufacturing plant in the UK, able to produce a staggering billion cans a year. The plant is by US can-making giant Ball and is expected to employ 200 people when it opens next year. The facility features a rainwater harvesting system and innovative technology to mitigate machinery exhaust emissions. This will result in 20% less energy demand and 70% less water than traditional can-making processes.

Direction of travel

Chemicals and renewables are quietly thriving in the East Midlands too. In Earls Barton, another village more famous for its church, global chemicals company Scott Bader is investing £200m in a new plant.

The company is unusual – more than 100 years old and one of the first in the UK to be employee-owned, it was one of the founding partners of the UK’s Employee Ownership Association. Scott Bader will produce structural adhesives in the new facility which are used in a variety of markets including the automotive industry.

One reason for locating these manufacturing plants in quiet spots in the East Midlands is the strength in logistics. The M1 carves down the middle of the region and interconnection to the rest of the country makes it ideal for distribution.

The vast Daventry International Rail Freight Terminal is where rail meets road. Already the country’s largest rail freight terminal, with twice as many trains as the nearest rival, a third expansion plan is being completed to ensure manufacturers and retailers are able to keep supply chains moving.

Green growth

Another ingredient is the desire to embrace new trends. Environmental issues, for example, are big news in the region. Vaillant, best known for gas boilers, is investing to expand into heat pumps. At Belper in Derbyshire, where Vaillant currently produces half a million natural gas and liquefied petroleum gas boilers a year, capacity is switching to air-to-water heat pumps.

The government has a target of 600,000 heat pumps to be sold a year by 2028. Joe Dunn, plant director of Vaillant Industrial UK, says; “This is a fantastic opportunity for our existing team to develop our skill sets ready for our product diversification and create new roles for the local area.

“As the demand for renewable heating technologies grows at an unprecedented rate in the UK, the Vaillant manufacturing facility will be well placed to meet the demands of the market, contributing to government targets for the decarbonisation of heat.”

A Nottingham manufacturer is looking at the potential for hydrogen to replace fossil fuels. Luxfer makes gas cylinders for medical, fire extinguishers, and aerospace purposes. Its new venture is cylinders for hydrogen-powered cars.

In a public demonstration, Luxfer equipped a Welsh-made Riversimple Rasa hydrogen car with a

hydrogen-cylinder. The lightweight two-seater Rasa offers 300 miles of range, and refuelling is done with a nozzle in minutes – a dramatic advantage over electric vehicle charging times.

Open to innovation

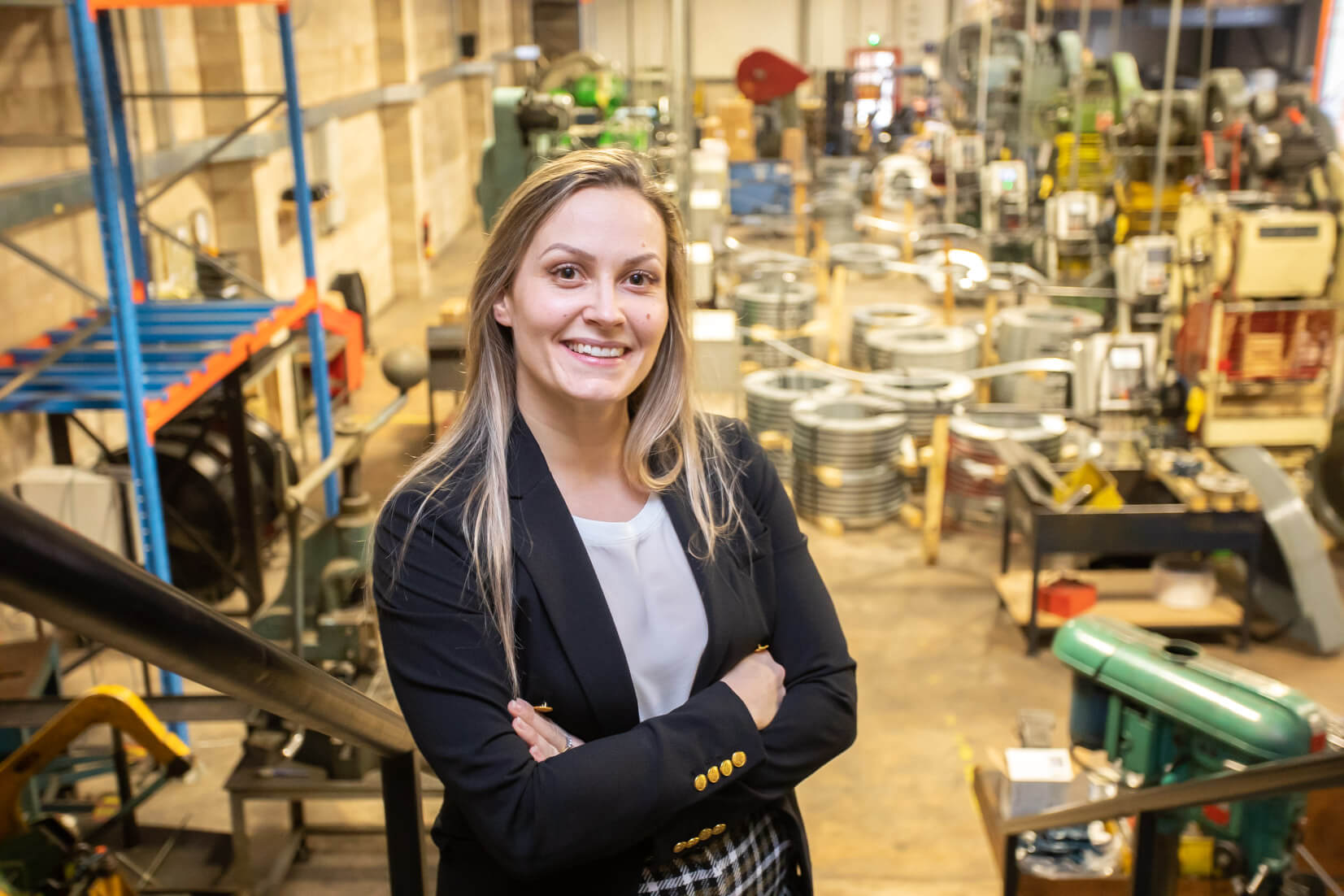

There’s also the trend for new working practices. A family-owned Derbyshire manufacturer of scaffold board end bands is experiencing increased productivity on the back of a switch to a four-day working week.

The business has invested nearly £100,000 into equipping 11 of its power presses with the latest servo feed technology from Bruderer UK, with a 12th on order.

“Working 39 hours a week and overtime during multiple points throughout the year is now a thing of the past. We’ve made the changes and have still achieved a 45% increase in capacity, helping us increase turnover and giving us the chance to go after new opportunities,” says managing director Laura Clarke, who is the granddaughter of founder Derrick Telford and who took over from her mother in 2019.

It may not be obvious, but the region is bristling with investment and innovation. You just need to know where to look.

News in Brief

- South Derbyshire’s First Fence is growing at 35% a year. Founded in 2010, the manufacturer of security and temporary fencing passed £26m in sales in 2021 and is looking to take on almost 50 new staff to sustain its current growth rate.

- Japanese machine maker Matsuura UK has opened a new Additive Manufacturing Centre directly adjacent to its Leicestershire HQ. The new facility plans to be the UK’s foremost centre of excellence for 3D printers of all materials and types.

- Little Moons is a niche brand of Japanese treats whose products went viral during lockdown. TikTok influencers filmed themselves searching for Little Moon mochi ice cream balls in supermarkets leading to skyrocketing social media engagement and sales. Now, the company is capitalising on the publicity with a new factory in Cransley Park, Northamptonshire.

- Rayden Engineering Limited, a specialist in the manufacture and installation of high-pressure pipework systems, has made sizeable investments in new vehicles and equipment following a number of high-value contract wins. In addition, it has recently refurbished the one remaining British Rail building on the former British Rail site at Wentworth Street to create a high-tech workspace for 18 additional staff.

- The East Midlands Freeport, located on three sites near Derby and Nottingham, was announced as a successful bid by the UK Government in 2021 and is currently under development. The aim is to create hubs of prosperity by cutting documentation for imports and tariffs. “This free trade zone, which will have a focus on innovation, low carbon and trade, signals the direction of travel for the East Midlands economy – giving investors something tangible to back in order to deliver the inward investment and jobs that will enable growth,” says East Midlands Chamber chief executive, Scott Knowles.

“Near the village of Catesby, an ambitious project has converted an old Victorian railway tunnel into a one-of-a-kind wind tunnel and performance facility”

Above: Laura Clarke, Managing Director at Chilwell Products

“A third expansion plan will ensure manufacturers and retailers are able to keep supply chains moving”

Below: Little Moons’ sweet treats are the result of two years tinkering and tampering with different recipes and techniques