Support is on hand for Scotland’s High Value Manufacturers

Regions Scotland

Above: In December 2021, the first turbine was installed at Seagreen, situated around 27km off the Angus coast. The £3bn project will become Scotland’s largest and the world’s deepest fixed bottom offshore wind farm once complete in late 2022/early 2023. Credit: SSE Renewables

Despite being dented by the global pandemic, which saw Scotland’s manufacturing output shrink by about a quarter, a range of public sector initiatives are helping innovative businesses that create value and jobs.

Rosemary Gallagher

Above: CuanTec’s new prototype film – CuanSave – is 100% natural and 100% compostable made thanks to the company’s proprietary chitin extraction process. Credit: CuanTec

Along with most of the economy, Scotland’s manufacturing sector has endured tough times over the last few years as a result of the global Covid pandemic and other headwinds, such as Brexit and the conflict in Ukraine.

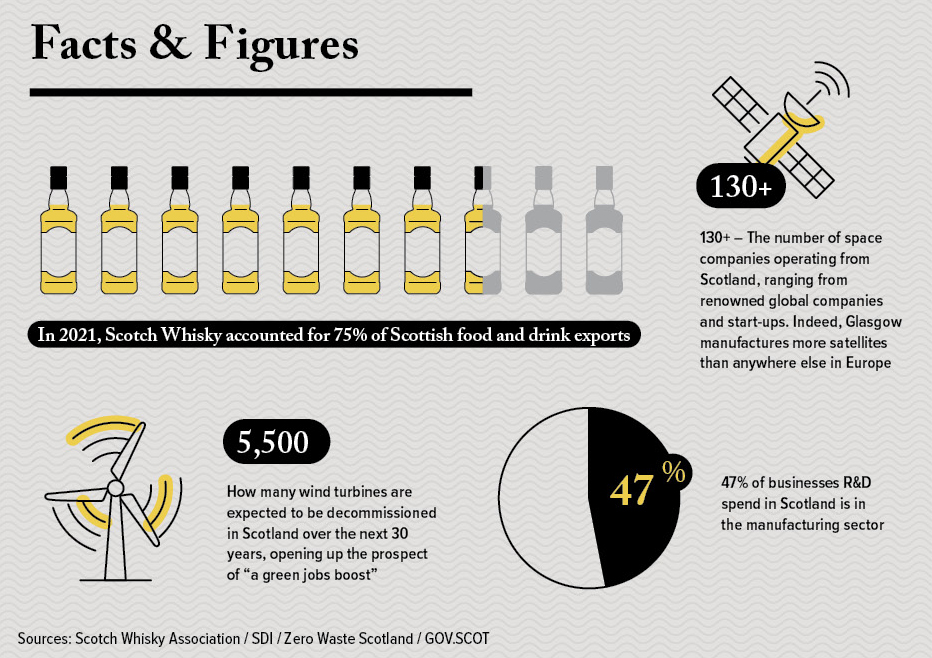

According to the Scottish Government’s recovery plan published last year, the country’s manufacturing exports were worth £30bn and accounted for 61% of trade with the EU in 2018, well before the pandemic. And 2019 figures showed that manufacturing was worth

£12.5bn in GVA and employed 169,000 people in Scotland. More recent statistics illustrate the impact of coronavirus with manufacturing output contracting by almost a 25% between the second quarter of 2020 and 2021.

Despite this relatively gloomy picture, there are signs that the longer-term future of Scotland’s manufacturing sector is looking bright. This is partly thanks to the creation and growth of innovative high-value businesses and an increasingly effective public sector support network.

Support

There are several initiatives in place, or being developed, to boost Scotland’s manufacturing sector and encourage innovation, rather than retain a reliance on more traditional global success stories. This includes the Scottish Government’s Making Scotland’s Future programme which is shifting from a focus on recovery to having a lasting impact.

“High value manufacturing splits into two bits. There’s the process side where manufacturers have invested in their operations, premises, automation and have connected their facilities. The other side is their products or services,” says Jerome Finlayson, head of High Value Manufacturing at Scottish Enterprise.

“A lot of businesses look at the processes, but haven’t invested in developing and being innovative around their products. For me, high value comes when the business has both a strong manufacturing process and a strong product or service proposition.”

Productivity

One of the main problems in manufacturing in Scotland – and the UK as a whole – has been identified as low productivity compared to other nations. Small and medium-sized businesses (SMEs) with fewer than 20 employees make up about 94% of Scotland’s manufacturing base so a key public sector aim is to better engage with them.

“We’re looking at the SME base and identifying clusters where there are lots of small companies with low productivity, such as in metal fabrication, construction and food,” Finlayson explains. “We’re developing programmes around SME engagement and looking at the five capabilities of strategy – leadership and management, operational

capability, digital, and product and service innovation.”

Initiatives

The Scottish Government is pumping millions of pounds into the National Manufacturing Institute for Scotland. NMIS is designed to be an industry-led international centre of expertise which will make Scotland a global leader in advanced manufacturing. It is scheduled to be fully operational in autumn 2022.

NMIS HQ will be located in Renfrewshire close to Glasgow Airport and the existing Advanced Forming Research Centre (AFRC) as part of the Advanced Manufacturing Innovation District Scotland (AMIDS). Along with the Lightweight Manufacturing centre (LMC), AFRC forms part of the wider NMIS group. LMC focuses on manufacturing with lightweight materials, such as carbon.

It’s hoped that such interventions will boost Scotland’s high value manufacturing businesses, develop relevant skills and support the nation’s drive to net zero.

“Scotland and the wider UK are global leaders in manufacturing and engineering, and it is crucial that we retain the skills we already have within these industries, supporting those at risk into new roles, while attracting new talent to continue to lead the way in the future. It is vital that we develop skills in areas of growth, not just for these individuals, but for our wider economy,” says Stewart McKinlay, skills director at the Manufacturing Skills Academy, part of the NMIS group.

“We are looking at where there is demand for work and where the opportunity lies, not just in the present day but as we look to future trends, and we are matching training to this,” he continues. “As we embark on the race to net zero, manufacturing has a key role to play, and there is definite demand, not only for green jobs, but for the greening of jobs in which we are making a role or process more sustainable.”

“There is a long and challenging road ahead for manufacturers worldwide,” adds Dr Katya McKenna, SME engagement lead at NMIS. “The good news is that we have highly skilled and innovative organisations to help overcome such issues; however, it is crucial that we bridge the gaps between a desire for diversifying operations and tangible and practical solutions for how to get there.”

Innovation

Scottish Enterprise and others, including the country’s universities, are backing a diverse range of businesses looking to bring something different to the manufacturing sector, whether that be in food and drink, aerospace or tackling climate change.

For example, sugar beet growing and processing in Scotland could create hundreds of jobs and support Scotland’s net zero goals, according to a study in 2021 funded by Scottish Enterprise and produced by the Industrial Biotechnology Innovation Centre (IbioIC).

It found that growing sugar beet and processing the crop at a purpose-built biorefinery facility – possibly in Dundee or Grangemouth – could create jobs across the supply chain while cutting carbon emissions.

Sugar extracted from sugar beet can be used in the production of ethanol as a natural and sustainable substitute for petroleum-based chemicals used in a range of household goods, as well as antibiotics, therapeutic proteins, and for transportation. The study built on crop trials in 2020 that found Scotland can grow sugar beet at competitive yields.

Launching the report, Mark Bustard, CEO at IBioIC, said; “Bio-based production is the future of manufacturing in a net zero Scotland and sugar beet is at the core of Scotland’s opportunity to develop a sustainable feedstock and compete on the global stage.”

Another example of innovation comes from University of Strathclyde spin-out, pharmaceutical firm Fitabeo Therapeutics which aims to save global healthcare more than £600m a year. The firm is about to start pre-clinical trials of its first two products, developed using its oral thin film drug delivery system.

“I feel very positive about the future of high value manufacturing in Scotland. I’ve never seen the support landscape look so strong – the challenge we have is to direct that support to SMEs,” concludes Jerome Finlayson. l

News in Brief

- Family-run commercial textile manufacturing business, The Beal Group, has recently completed an ambitious relocation and expansion project in Cumbernauld and is targeting net zero opportunities. With a £4m injection of funding it is poised to create more than 40 new jobs.

- Global health and nutrition company Royal DSM has chosen Dalry in North Ayrshire as the manufacturing site for its methane emission reduction project. Its feed additive leads to a 30% or more reduction in methane produced by cattle.

- Isle of Raasay distillery, owned by R&B Distillers, is working with the University of Strathclyde to implement sustainable practices and reach net zero as part of a Knowledge Transfer Partnership (KTP).

- Govan-family business Rearo, which designs and manufactures durable worktops, wall panels, and flooring for commercial use, as well as domestic bathrooms and kitchens, has recently invested more than £500,000 to transform its production process and develop new products.

- Mitsubishi Electric Air Conditioning Systems Europe has invested £15.3m in its Livingston manufacturing facility, with Scottish Enterprise support, to meet increasing European and UK demand for its low carbon heat pumps that tackle climate change.

- University of Strathclyde start-up CuanTec – headquartered in Oban – which converts shellfish industry waste into high-value, chitin-based products, including biodegradable food wrap, has secured significant investment from Hive Energy, one of the UK’s largest renewable energy and cleantech project developers.

“The longer-term future of Scotland’s manufacturing sector is looking bright… partly thanks to an effective public sector network”

Above: NMIS has been designed as a collaborative space where universities, companies and entrepreneurs can come together to do short-term innovative projects up to prototype stage. Credit: University of Strathclyde

“Bio-based production is the future of a net zero Scotland”

R&B Distillers, which owns Isle of Raasay distillery, is aiming to reduce the carbon footprint of its operations by a further 40% by 2030, in comparison with 2018. Credit: Isle of Raasay Distillery