London & South East: UK’s Highest Level of Business Confidence in Next 12-Months

Regions: London & South East

Artist’s impression of Brompton Bicycle’s revolutionary new factory in Kent. Credit: Daniel Nelson

A reliance on electronics, food and drink and transport left the UK’s second largest manufacturing region heavily exposed to lockdown disruption, but rising levels of business investment reflect a confident outlook.

Credit: Tate & Lyle

Only around 8.4% of London and the South East’s output is generated by manufacturing, below the UK regional average of 10%, but this is still £22.5bn – the second-highest region after the North West. This serves to illustrate just how strong the region’s financial and service sectors are.

High-tech, high-value engineering generates substantial economic gains for London and the South East, with a large concentration of internationally-important companies in aerospace, defence, automotive and electronics. Take space, as an example. The region hosts 767 space organisations (450 in the South East and 317 in London), representing more than 40% of the UK space industry and generating double that percentage in terms of total income.

However, supply shortages for key components, especially semiconductors, are being felt most acutely by exactly these high-tech sectors. The region’s other dominant sector, food and drink, faces similar supply chain challenges.

Need for stability and certainty

More than 80% of the South East is classified as rural. Whether town or country, there has been a sustained boom in craft ale and gin, which has produced a thriving community of winemakers, brewers and distillers. London alone has 24 gin distilleries – and possibly more by the time you read this.There are almost 50 vineyards in Kent alone, including several of the UK’s leading winemakers – Chapel Down, Gusbourne and Hush Heath, as well as prestigious French producer Taittinger.

Faversham in Kent is also home to Britain’s oldest brewery, Shepherd Neame, which produces the iconic Bishops Finger and Spitfire ales, among many others. Beer has been brewed on the site for centuries and today the brewery produces more than 50 million pints a year, exports to more than 35 countries and operates over 300 pubs across the region.

Outside of alcohol, London and the South East are equally well represented in every slice of the food and drink sector, from teas and snacks to free-from and gourmet offerings.

Having spent two years contending with lockdowns and operating restrictions in the hospitality sector, food and drink producers – the majority of whom are small, independently owned businesses – hoped 2022 would bring greater stability and certainty. Those hopes were short-lived for starkly apparent reasons.

Despite record commodity prices, labour shortages and the war in Ukraine impacting supplies of key ingredients, such as vegetable oils and cereals, the region’s manufacturers remain cautiously optimistic for the future.

London and the South East have one of the highest levels of business confidence for the coming 12-months, second only to the North East, according to Make UK’s latest Manufacturing Outlook. Domestic and export orders remain high, spend on recruitment and skills is rising and investments in new machinery and production capacity are likely helping to keep moods buoyant. At least for now. l

News in Brief – London

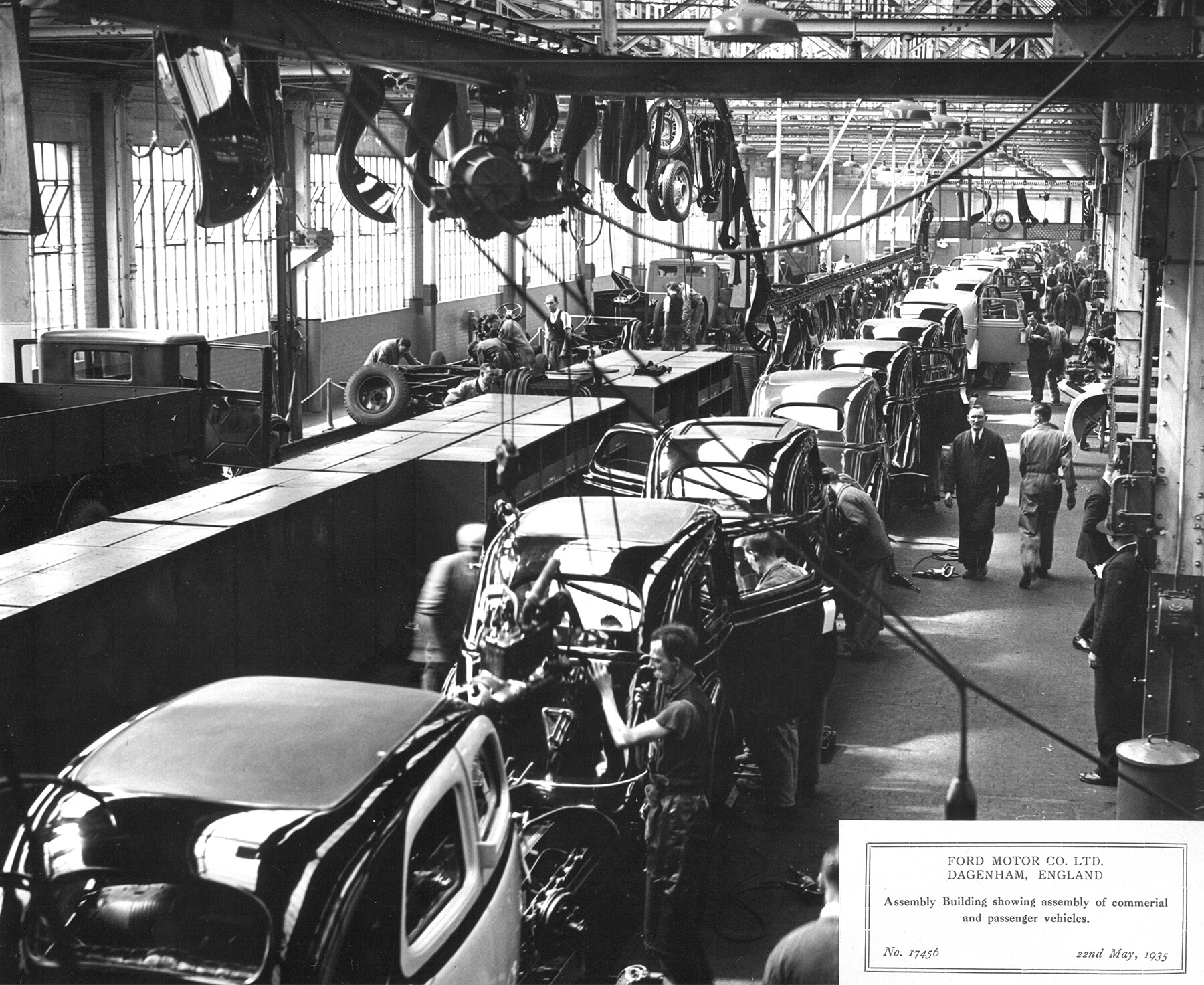

- Ford of Britain, based in Dagenham, has operated in the UK for nearly 91-years. Almost 11 million cars, trucks and tractors have been built over 72-years of vehicle production. The Dagenham site has produced close to 50 million engines. Dagenham continues to play an important part in Ford’s European operations, building advanced diesel engines for many Ford cars and commercial vehicles. There are plans to convert the original Ford Factory into a 3,500 home village. Shops, offices and a school are set to be built on the 45-acre site.

- The TATE & LYLE SUGARS Thames Refinery in Silvertown, London remains the biggest sugar refinery in the EU and one of the largest in the world, with a capacity of 1.2 million tonnes per annum. The UK currently imports around 600,000 tonnes of sugar annually (2020). Last year, £172m worth of cane or beet sugar were imported into the UK from non-European Union countries. (Sources: Statista and Ragus). The sugar tax means that manufacturers of soft drinks containing more than 5g of sugar per 100ml pay a levy of 18p a litre to the Treasury.

- A small shout out to Mustard Foods of SW19, London. This news dates from 2021 but needs repeating. From producing over 30 tonnes of food per week for 32 large UK restaurant groups, to zero, Mustard Foods was faced with a huge challenge. But from March 2020 to April 2021, the company collaborated with three different non-profit organisations to deliver 475,000 meals to the NHS frontline and vulnerable people, in more than 15 hospitals and centres across London and the South West of England. Bravo Mustard!

- London-based water technology company, Bluewater Bio, has gone from strength to strength since a new management team took the helm in 2015. Focusing on delivering advanced and environmentally-friendly water technologies to those regions most affected by water scarcity, it is now recognised as the fastest growing water tech company in the UK and Europe. “The installation of our technology has prevented pollution and increased the amount of clean drinking water. Our continued industry-leading performance and growth is a testament to this strategy,” says Richard Haddon, executive chairman and CEO.

- HSSMI is a sustainable manufacturing consultancy devising engineering solutions to reduce carbon emissions and save resources, especially in automotive. A new Virtual Training Creator (VTC), developed by HSSMI with funding from the XR4ALL platform, seeks to make the process of workforce training by using virtual reality. By providing a plug-in with user interface template and pre-developed functions for “Unreal Engine”, the VTC tool can help manufacturers take their training approach from the physical to the digital environment. The development requires no coding and can be easily implemented by companies that want to upskill their employees. The plug-in can be downloaded for free from the XR4ALL platform.

News in Brief – South East

- Hampshire-based aluminium die casting foundry, MRT Castings Ltd, has been honoured with a Queen’s Award for Enterprise in International Trade, in recognition of its outstanding export growth over the past three years. Based in Andover, Hampshire, MRT specialises in complex components for high specification, low to medium volume markets, including medical, defence and specialist electronics sectors. Overseas sales have grown by 437% over the past three years and the proportion of sales exported has increased to 85% of total sales. To support this growth, MRT moved into a purpose-built new foundry at the start of 2022, kitted out with the latest diecasting and CNC machining technology to create one of the most technically advanced facilities of its kind in the UK. “A Queen’s Award for Enterprise is the ultimate accolade for a UK business, and to have won two just six years apart is testament to the relentless energy and enthusiasm of our team,” says managing director,

Phil Rawnson. - Megger, the electrical testing company, has secured a £168m loan secured by a £138m loan guarantee from UK Export Finance. International Trade Secretary Anne Trevelyan announced the UKEF-supported guarantee at Megger in Dover on 16 May. The loan will be partly used to increase manufacturing capacity that will boost exports and safeguard jobs. Jeremy Simpson, Megger CFO, says; “The government, via UKEF, has recognised that Megger is a growing company that designs and makes high value-added products, based in the UK with strong global exports, and growth prospects in new markets.

The money will be invested in several areas, including: our smart grid solutions and testing technology through growing the company’s product lines, to help fund an essential factory extension here in Dover and to provide additional working capital to help the company fulfil overseas export contracts.” The company is transforming from a manufacturer-only of testing hardware to a business that provides asset health monitoring using data capture and analysis technology that helps, among other things, grid operators to manage loads reliably (see profile on page 172). - Pharmaceutical temperature-controlled specialist Tower Cold Chain has doubled its UK staff numbers over the past three years and opened a new 26,000 sqft headquarters and centre of excellence in Theale, Reading. This includes a dedicated innovation centre to enhance its design and laboratory testing capabilities and new product development. Its overseas sales and the proportion of total sales exported have increased significantly over the past 18 months, with the company seeing particular success in the US, Germany, Belgium, South Africa and China. This coincides with the expansion of its global hub network to maximise proximity and availability to customers in all regions.

- Plans are underway at the UK’s largest bicycle manufacturer, Brompton Bicycle, to open a new £100m factory in Ashford, Kent. The new site is expected to increase production capacity to around 200,000 bikes a year, up from 80,000 currently, with staff numbers similarly rising from 850 to 1,500 once fully operational. Additionally, the proposed development is forecast to support around 4,000 local jobs, including supply chain jobs, jobs supported by the spending of staff and the factory operation itself. Brompton’s current factory in Greenford, West London will reportedly continue to operate until at least 2030. “London was the inspiration for the Brompton and our success is in large part due to our diverse and skilled staff who continue to nurture and develop our company. By choosing Ashford we can retain this strong connection to London and the UK, whilst being on the doorstep of Europe” says CEO, Will Butler-Adams OBE.