East of England – Well placed for a post-pandemic boom

Regions: East of England

Above: An aerial view of the Adnams brewery in Southwold. Credit: Anthony Cullen

The diversity of the manufacturing sector across the East of England means things are getting back to full capacity more quickly than in some other parts of the country.

Adam Aiken

The production line at Lintott Control Systems. Credit: Lintott Control Systems

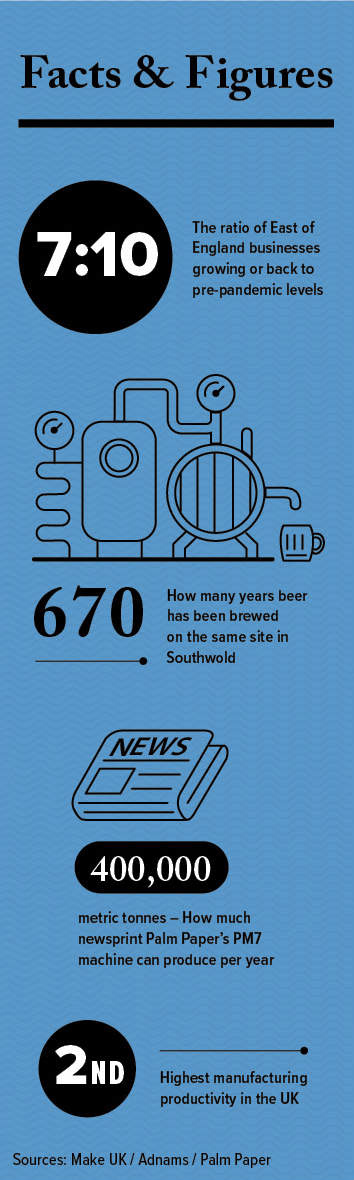

The start of 2022 has seen strong output (+27%) and total orders (+30%) in the East of England, with the significance of the region’s food and drink sector likely playing a part following the full post-pandemic reopening of the hospitality industry.

According to the quarterly Manufacturing Outlook survey from Make UK and BDO, recruitment intentions have improved significantly since the end of 2021, although investment intentions have fallen.

Make UK’s regional director, Charlotte Horobin, says that although the threats in the East of England were the same as elsewhere

– supply chains, costs and recruitment – manufacturers in the area were bouncing back more positively.

“The East of England has come bouncing back positively, far more positively than we are seeing in other parts of the country,” she says. “I think that’s down to the diversity of manufacturing we’ve got.

“Three out of 10 are growing in the region at the moment, four out of 10 are fully operational or operating as they were pre-pandemic, and three out of 10 are still in recovery mode. Other parts of the UK have high density industries whereas the spread in the East of England benefits us.”

Charlotte also points towards a can-do outlook in the region. “There’s a certain attitude in the East of England,” she says. “Perhaps because it’s not seen as a natural hotbed for manufacturing, there’s an attitude of coming together. So, if government help is not forthcoming, manufacturers are getting together and making changes themselves.”

Working in partnership

It’s a view reflected by Jamie Thums, COO of Norwich-based Lintott Control Systems and chair of New Anglia Advanced Manufacturing and Engineering (NAAME), which is the LEP-recognised sector group for Norfolk and Suffolk.

“We’re on the cusp of quite a significant opportunity to really put manufacturing on the map,” he says.

“In the East of England, we are doing something different. Manufacturing organisations recognise that there are significant benefits in working together to develop the workforce of tomorrow, to build and further connect the supply chain, and to work and innovate together.

“There’s a strong appetite and buzz to produce opportunities for each other while championing the sector. We are helped by the mix of businesses. There’s not just one major organisation taking the lion’s share.”

Lintott Control Systems designs and manufactures digitally integrated, factory-built equipment and process software.

Thums says the business, which was acquired by Galliford Try last year, was positive about the future; “The next 24 months look incredibly exciting. We’re busy pioneering new developments, growing our team and competencies, making a positive difference, and continuously reinventing ourselves.”

‘Handmade In Hethel’

It’s also all systems go at Lotus, the iconic car manufacturer based in Hethel, near Norwich.

Since the company became majority-owned by Geely in 2017, the workforce has nearly doubled and there has been investment of £100m in the business, including two new production halls. The main assembly hall is the size of one-and-a-half football pitches.

Two models are assembled at Hethel. The Emira went into production early in 2022, and the much-anticipated Evija – an EV hypercar – will go into production in the spring.

“A level of automation has been introduced into the production of the Emira, and this improves overall quality and repeatability during the manufacturing process,” says executive director of operations, Kris Elston.

“Automation is supporting our growth and improving our process efficiencies. Our cars remain ‘Handmade in Hethel’ because we have the right balance between advanced technology and our highly-skilled operatives.”

Meanwhile, Lotus picked up the title of ‘Manufacturer of the Year’ at the News UK Motor Awards. One of the judges, The Sun Motors Editor Rob Gill, commented; “We are starting to see the first harvest from Geely’s huge investment in Lotus and, wow, the Evija and the Emira are simply sensational.”

Upping efficiencies as well as value

Food and drink manufacturing is one of the East of England’s staples, and Andy Wood, CEO of Adnams, the brewer based in Southwold on the Suffolk coast, describes the region as the “breadbasket of the UK”.

He says the usual factors were having an impact, but planning and deep relationships were paying dividends; “Like others, we continue to be impacted by the supply chain issues and price elasticity.

“We have strong and established relationships with our suppliers, who often we have worked with for decades, which is important to us. Working with our key suppliers incredibly closely, we have been able to identify, understand and overcome potential issues.

“We have worked hard on digital transformation and we have been able to increase efficiencies while increasing value for our teams and customers to make things easier and simpler.

“We, like those in other industries, face many uncontrollable elements, but we control what we can, understand the impacts of possible changes and make extensive plans so we can react immediately to any possible changes,” he continues.

Dividends of diversity

Some manufacturers have been well placed to deal with the fallout from the seismic issues of recent years.

“The sector is the strongest I’ve ever witnessed, and our markets in America and Canada have exceeded our expectations,” comments Darren Smith, managing director of Agrimech Services, an award-winning machinery automation business based near Wisbech.

“During Covid, people haven’t wanted to have other people around them, but they still need to produce, so they have invested in automated machinery. Also, the European workforce heading home after Brexit has made it more difficult for employers to get labour. It’s not a case of ‘machine versus person’ anymore as the person isn’t there to do it.”

“As a business, we are not holding back now, and we are making more machines in this country to rival those made in Europe and all around the world,” he adds.

Meanwhile, Warren Services, a subcontract machine builder in Thetford, on the Norfolk-Suffolk border, enjoyed a bumper 2021.

“We have come through Covid in a pretty good position. We stayed operational throughout the pandemic so we didn’t have the problems that might have come with restarting,” says chairman Will Bridgman.

“Last year we had 30% growth, which is the highest ever for us. We had been working with a client on technology used in online grocery delivery, and that was very helpful for us because it was a time when lots of people wanted groceries delivered.

“The theatre and live music side of the business, which had been very good for us previously, wasn’t happening, but our diversity paid off. We are specialists at being diverse, and that pays dividends.”

News in Brief

- The PM7 at Palm Paper’s site in King’s Lynn, with a working width of almost 11 metres, is the world’s widest, largest and most powerful newsprint machine in the world. It can produce 400,000 metric tonnes of newsprint a year.

- Suffolk-based EO Charging, which manufactures EV charging stations and develops cloud-based management software, distributes to more than 35 countries. Its technology is used by Amazon and DHL and it was ranked 45 in this year’s FT1000 list of Europe’s fastest-growing companies.

- Based in Snetterton, Norfolk, pet food manufacturer Natures Menu has been running for over 40 years and now employs more than 250 people. The company has continued to grow, and now produces an estimated 20,000 tonnes of raw and natural food for cats and dogs each year.

- Sudbury-based manufacturer and supplier Caribbean Blinds has grown 35% year-on-year since January 2017. The family-run firm is currently on track with its ambitious strategy to quadruple in size over the next five years.

- Cambridge Precision manufactures critical components for emerging technologies around the globe. Focusing on the med-tech and high-tech sectors, the company is growing rapidly and expects to hit

a turnover of £12m this year. - Rega employs 170 people, producing 6,500 hi-fi products by hand every month, including 4,500 turntables. The Southend business exports to 55 overseas markets and has an annual turnover of £20m.