The North East: Where Traditional Strengths Meet Disruptive Innovation

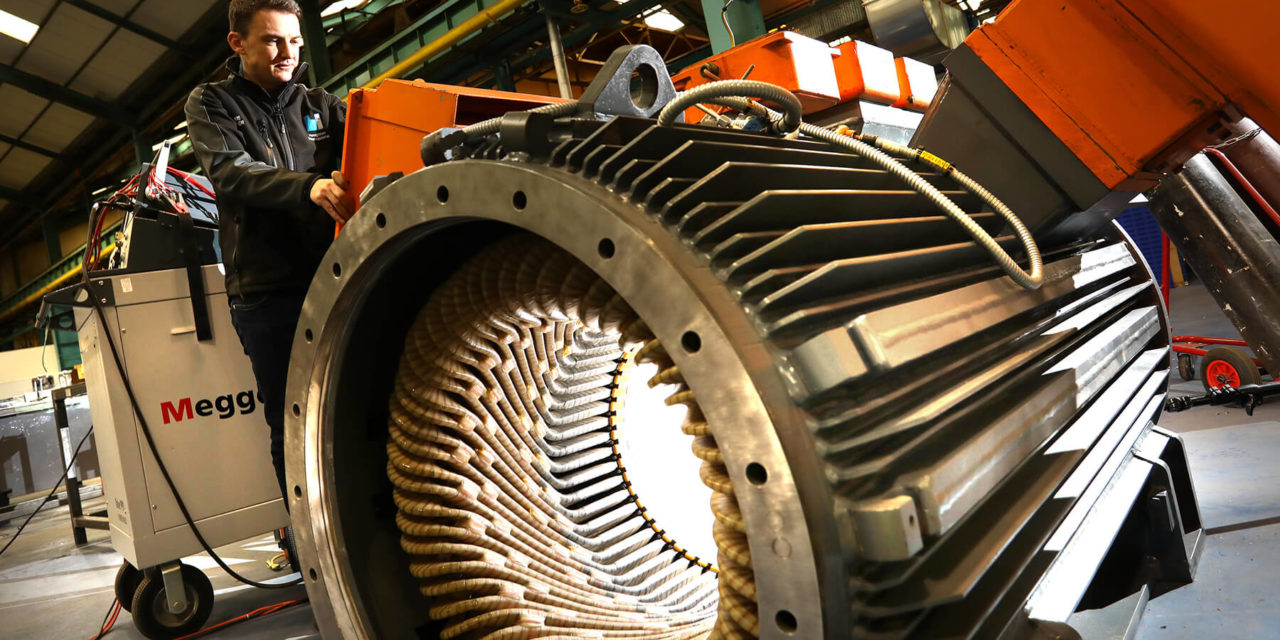

Above: Houghton International is one of the UK’s few companies that can refurbish and maintain nearly all industrial electric machines – generators and motors. It has won new business from around the world and in 2021 won a Make UK award for its successes. Credit: Houghton International

Skills forged in the shipyards and collieries are still prevalent across an industry that is constantly evolving to exceed the needs of a challenging global marketplace.

Above: 100% electric trains built at Hitachi Rail’s Newton Aycliffe factory offer a more sustainable alternative to domestic flights. Hitachi Rail

Accounting for 15.3% of GVA and 11.3% of employment, manufacturing and engineering truly are the cornerstones of the North East economy. With unrivalled land and natural assets, two major airports, several international ports and direct road and rail arterial routes to London and Edinburgh, the region is perfectly situated for heavy-duty exporters.

Genuine titans of industry have found productive and profitable homes in this part of the world. As the North East’s age-old heavy industries wound down, traditional jobs were replaced by advanced roles on production lines at the likes of Nissan, Komatsu, Unipres, Caterpillar, Nestlé, GSK and Technip FMC.

Traditional engineering strengths were developed and Kaizen practices introduced by the likes of Nissan and Komatsu spurred a drive towards continual improvement and a broader industrial skills base.

“Our aim is to continue growing our presence in the North East and I’ve no doubt we will because we have the skills and a talented and loyal workforce to suit,” explains Paul Blanchard, managing director at Komatsu UK.

Automotive and engineering abilities have helped draw in the likes of Hitachi Rail, which found a hugely successful home in Aycliffe having invested more than £80m in an ultra-modern train assembly plant.

Nissan Motors, which opened its Washington plant in 1984, has enjoyed enormous success in the North East, with the plant named “the most productive car manufacturer in Europe” on multiple occasions.

The firm chose Washington for the manufacture of, the world’s first mass-market all-electric vehicle, the Nissan Leaf, and it has recently invested in battery manufacturing at the huge factory.

In the past three decades, the region has grown its reputation for delivering excellence in automotive manufacturing, rail, aerospace, electronics, pharmaceuticals and subsea engineering, not to mention a well-connected supply chain, supporting large numbers of jobs.

The North East is nothing if not resilient. As the former ICI operations collapsed, smart management buy-outs and new company start-ups were created, with the industrial hubs of Wilton, Seal Sands and Stockton continuing to support tens of thousands of chemical and pharma manufacturing jobs. Indeed, Fujifilm Diosynth Biotechnologies has created a new plant to manufacture the Novovax Covid vaccine at its Billingham plant. A move expected to boost the 890-strong workforce by a further 350.

The region has a constantly developing skills base, with high-quality apprenticeships and graduates signing up to play a role in a productive, innovative and highly-developed workforce.

More than 116,000 people work in manufacturing roles, including 69,000 specialist workers employed in advanced manufacturing. Over 110,000 students study at the region’s

five universities, with more than half studying Science, Technology, Engineering and Mathematics (STEM) subjects.

And despite the ongoing impact of the Covid pandemic, North East manufacturers are consistently among the most optimistic in the country.

A recent report from Make UK and business advisory group BDO found that firms in the region are best set to recover from losses suffered during the pandemic and accelerate ahead of other parts of the economy.

Orders, confidence and hiring intentions all ranked strong among manufacturing firms, according to the report, while investment intentions by businesses increased.

The North East also boasts exceptional sites and transport infrastructure. More than 2,000 acres of space is available at low-cost development sites close to major original equipment manufacturers (OEMs) with superb access to ports, airports, rail and road networks.

Sunderland and South Tyneside Councils formed a productive partnership to create the International Advanced Manufacturing Park (IAMP) – a project labelled ‘nationally significant’ by the UK government.

With the potential to create upwards of 7,000 highly-skilled advanced manufacturing roles, IAMP has proved an attractive proposition, since work completed on phase one of the site in November 2020. Global giants such as SNOP UK and Faltec are already on-site, and Envision AESC, which has secured planning consent for the construction of a £450m 9GWh-capacity gigafactory, is set to arrive too.

Such is the scale of recognition of the importance of IAMP across the sector, all developable land brought to market in the first phase has been snapped up, with work now progressing on development of phase two.

Based on land just north of Nissan UK, more than 160,000 sqm of floor space at the 150-hectare manufacturing park has been taken up, with phase two set to bring a further 221,997 sqm of precious prime industrial space to the market.

Speaking on the early success of IAMP, Councillor Graeme Miller, leader of Sunderland City Council, says; “When complete, the park will be a world-class destination for advanced manufacturing creating thousands of jobs, but to see the value of this project to the region already – with so many people from the North East’s construction sector having worked on the development – shows just how many important businesses from an array of sectors we already have right here on our doorstep.”

The North East’s advanced manufacturers are also focused on the future. Great leaps forward in innovations in technology, robotics, automation, electrification and artificial intelligence have been pioneered by some of the region’s largest manufacturers, Tharsus Nissan, Avid Technology and Komatsu UK, all leaders in their respective fields.

Alongside IAMP, the region boasts a growing collection of pioneering research and development facilities, including the National Innovation Centre for Data, PROTO: The Emerging Technology Centre, the Centre of Excellence for Sustainable Advanced Manufacturing and no less than five Catapult centres.

The North East’s historic skills in manufacturing and engineering are also benefitting from the growth of the digital sector. Ground-breaking work across the tech industry is playing a major role in the future of advanced manufacturing. Developments such as Industry 4.0, autonomous vehicles and green tech are all proving vital to the future development of the sector and beyond. Companies and institutions across the region are collaborating to transform high potential ideas into new products and services to drive economic growth both regionally and nationally.

News in Brief

- Newcastle-based Houghton International is powering the world through its electromechanical engineering and repair services. From high-speed rail and wind turbines to waterworks, the company is the first port of call for businesses the world-over looking to improve the performance, lifespan and green credentials of their electromechanical assets. Since relocating to a new 135,000 sqft facility in 2020, the company has gone from strength-to-strength, bringing on board a raft of blue-chip clients, creating scores of jobs and investing heavily in its equipment and facilities. Through its continued investment in its award-winning maintenance and repair service, the firm has also played a key role in helping British manufacturers safeguard their supply chains post-pandemic, by extending the life and quality of existing machinery and reducing the need to import from overseas suppliers. Not only has this helped make UK supply chains more environmentally sustainable by slashing emissions, but the onshoring of maintenance and repair work to the UK is also having a huge economic impact through increased jobs and opportunities for local suppliers.

- Californian firm Turntide Technologies, which is backed by Bill Gates, actor Robert Downey Jr and Amazon, has acquired three North East firms – Avid Technology BorgWarner Gateshead and Hyperdrive Innovation – in a £100m deal aimed at putting the region at the centre of the electric vehicle revolution.

- Scandinavian recycling start-up Wastefront is investing more than £100m to build a pioneering tyre recycling plant at Port of Sunderland. The new facility is due to be in operation by 2024 and create up to 100 highly-skilled jobs.

- County Durham’s Power Roll is carrying on the North East’s long tradition of energy innovation with the opening of the world’s first facility producing low-cost, lightweight, flexible solar film using the company’s patented micro-groove technology. When the film is produced at scale, manufacturing costs are forecast to be as low as a tenth of the cost of other flexible PV.

“Genuine titans of industry have found productive and profitable homes in this part of the world”

“In the past three decades, the region has grown its reputation for delivering excellence in automotive manufacturing”

Below: Paul Blanchard, Managing Director at Komatsu UK. Credit: Komatsu UK

“A recent report found that firms in the region are best set to recover from losses suffered during the pandemic”

Below: South Shields-based Ogel secured £50,000 from Tej Lalvani of BBC’s Dragons’ Den and a further £200,000 from crowdfunding to bring to market its revolutionary system that transforms waste plastic into building materials. Credit: Ogel