JCB leading the way for a zero carbon future

Supporter: JCB

JCB’s Chairman Anthony Bamford explains the revolutionary hydrogen technology pioneered by JCB which is driving the construction industry towards a zero carbon future.

You only have to turn on the news or read a newspaper to know that the threat of climate change is an increasingly real and pressing issue. With the target for the UK to be net zero by 2050 the onus is on all of us to reduce our carbon emissions.

As the Chairman of one of the world’s largest construction equipment manufacturers, I feel this particularly keenly. JCB manufactures diesel engines. We are currently producing 400 a day for our own range of agricultural and construction machinery and other leading OEM firms. However, with the Government’s commitment to end the use of diesel and petrol in cars, it is clear that we need to look at alternative means of powering our machines.

So, in July 2020, a team of JCB engineers set to work designing an engine for a digger that runs entirely on hydrogen. By December, the first working prototype was being tested.

While some car manufacturers’ previous attempts to produce hydrogen engines have been unsuccessful – as they simply tried to convert petrol engines – the team at JCB has managed to develop a high-performance, purpose-engineered zero-CO2 hydrogen fuel motor, which just emits steam from the tailpipe.

Benefits Of Hydrogen Power

For construction and agricultural industries, batteries are not always a viable option. In order to power heavy machinery, the batteries would need to be enormous and would therefore prove heavy in situ and expensive both to manufacture and to run.

There would also be charging issues when it came to recharging, as the machines often operate well away from existing infrastructure – be that on farmland, in quarries or on large and remote construction sites – and, of course, it would be impractical and unsafe to run electricity cables across the fields or the building site to charge the machines.

In addition, for an engineer who is used to petrol or diesel motors, to re-train on electric models means dispensing with much of what they know and effectively starting from scratch. The logistical problems would be colossal, especially in the developing world.

Hydrogen engines solve all these problems as they work on the internal combustion principle and will feel familiar to anyone who is used to diesel or petrol engines. Plus, the cost is roughly the same as traditional engines running on fossil fuels. Unlike batteries, they are not inflationary.

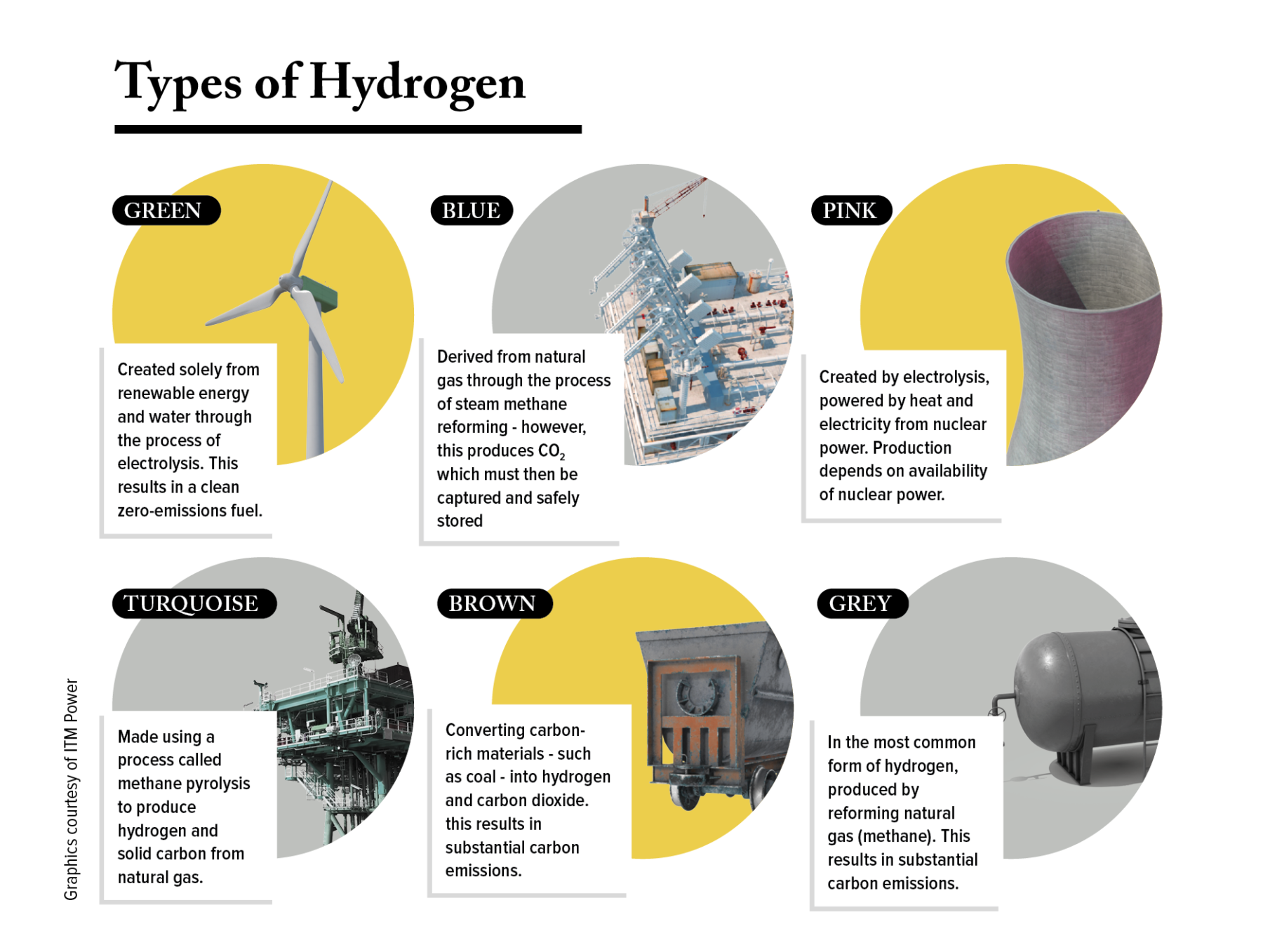

And the main benefit, of course, is that these hydrogen engines do not pump any carbon dioxide into the atmosphere, so they are entirely carbon neutral. For green hydrogen production, we can even utilise surplus renewable energy generated by solar or wind power which is currently going unused.

What Is The Next Step For Hydrogen Power?

Now that the technology is here, the next step is to encourage global governments and authorities to take it up. While the benefits of hydrogen power are hopefully clear for everyone to see, it is still a relatively new technology. So, it is crucial that we start to take the lead in getting the message out there.

And this begins at home. We were delighted to demonstrate our hydrogen-powered loaders to Prime Minister Boris Johnson in London in October 2021 and to others at the COP26 climate change summit in Glasgow. The reaction has been overwhelmingly positive.

Prime Minister Johnson said: “Great British manufacturers like JCB are developing innovative solutions to slash greenhouse emissions and advance the UK’s green industrial revolution.

“It was fantastic to see JCB’s super-efficient hydrogen engines, which could overhaul UK manufacturing, help us to rapidly reach our climate targets and ramp up the UK’s hydrogen economy – an exciting area that will be essential to tackling climate change, creating new jobs and attracting investment.”

My hope is that hydrogen power will start to be seen as a genuinely viable alternative to electric or battery-powered machinery within the construction sector and JCB is investing £100 million in its project to produce super-efficient hydrogen engines. A team of 100 engineers is already working on the exciting development with the recruitment of up to 50 more engineers now under way as we target the end of 2022 for the first machines to be made available to customers.

This commitment reinforces my conviction that hydrogen power will be a key part of the solution to respond the ongoing threat of climate change and that Britain can be firmly at the forefront of the hydrogen revolution.

www.jcb.com/en-gb/campaigns/hydrogen