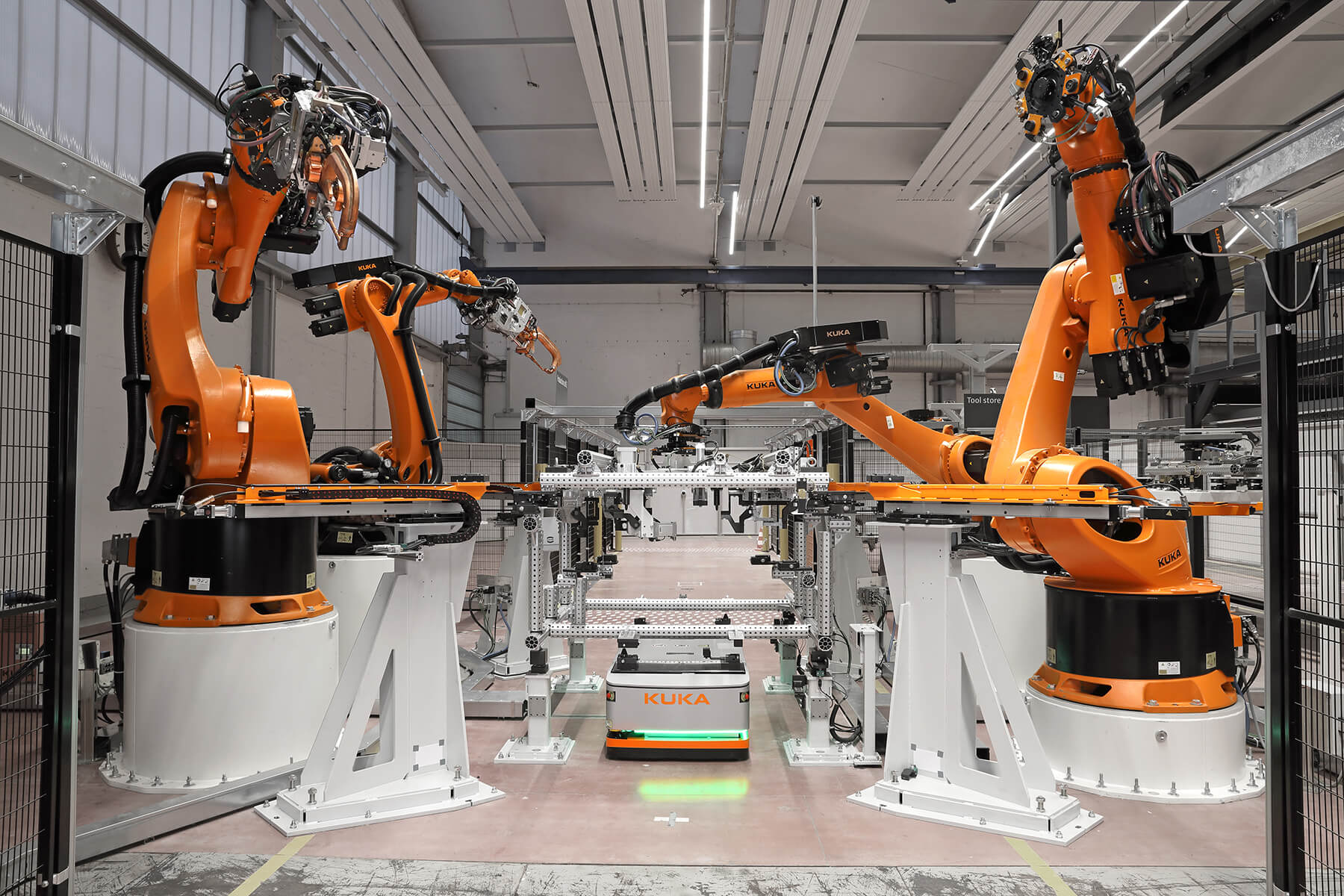

Production systems from KUKA: Scalable, flexible and efficient

Sponsor: KUKA Systems UK Ltd.

KUKA’s competencies in the conception, planning and implementation of cost-effective and technically efficient production systems are world-renowned. We are experts in system integration, be it for an individual production cell or a complete, turn-key production system.

Expertise and experience in systems engineering across industry are derived from a passion for automation and robot technology; innovation is our passion and reliable implementation is our strength.

Demand for automated production technologies, however, is broadening and the solutions that KUKA is able to offer its customers have evolved. Modular, scalable production cells form an integral part of our product portfolio. Flexible and portable modular cell concepts designed specifically to integrate into existing production landscapes.

Cell4_production and ready2_ systems enable the seamless integration of robot process automation into existing production environments for rapid adaptation thanks to pre-assembled, pre-configured components and easy commissioning. The perfect solution for simpler ways to increase productivity.

Traditionally delivering systems into the automotive and Tier 1 sectors, KUKA’s focus has diversified as the need to automate legacy processes has come to the fore. Welding, being just one. Value-driven automation systems are being endorsed as more and more businesses recognise the need to address challenges such as depleting skilled labour pools, and product integrity / quality output as a means to remain competitive.

System integration within the automotive and Tier 1 sectors is in itself changing, as a transition to HEV and BEV manufacture continues and many production principles that are well established, are simply being repurposed and applications such as welding are being integrated into existing process chains. Standard products for automation from across the KUKA portfolio are also being integrated into more complex engineering applications where considerations above and beyond maintaining competitive advantage exist.

Nuclear decommissioning and legacy waste retrieval from KUKA provide reliable and robust solutions for a variety of waste handling tasks, built upon 70 years of delivering automation expertise into one of the most hazardous environments imaginable since supplying parts to Berkeley nuclear power station in the 1950s

KUKA robots used in nuclear decommissioning are already available on the market, most commonly used in foundries and on car production lines. More advanced nuclear decommissioning solutions require the adaption of proven industrial standard technology to suit the unique and often complex challenges of this industry, making us the only off-the-shelf nuclear compliant robotic systems manufacturer.

Our spectrum of products also includes the appropriate robot peripheral equipment, from linear units to end effectors. Combined with cutting-edge software and innovative controllers, we develop individual solutions for your manufacturing processes together with you. Whether for maximum speeds behind the safety fence of your system, as a mobile solution for your I4.0 requirements or for direct collaboration between humans and machines in HRC operation.

Whether body-in-white production, assembly, welding, nuclear or assembly, KUKA’s automated production systems enable your business to get ahead of the market.

“KUKA’s automated production systems enable your business to get ahead of the market”