Adding up in Value

Technologies: Additive Manufacturing

Additive manufacturing is a maturing technology finding profitability in niches and quick wins. It has benefitted from the drama of global supply chain failure and now faces a positive path as we come out the other side.

Stephen Holmes

Above: 3D printed tooling used to hand form the panels for Alvis’ Graber nose. Credit: Alvis

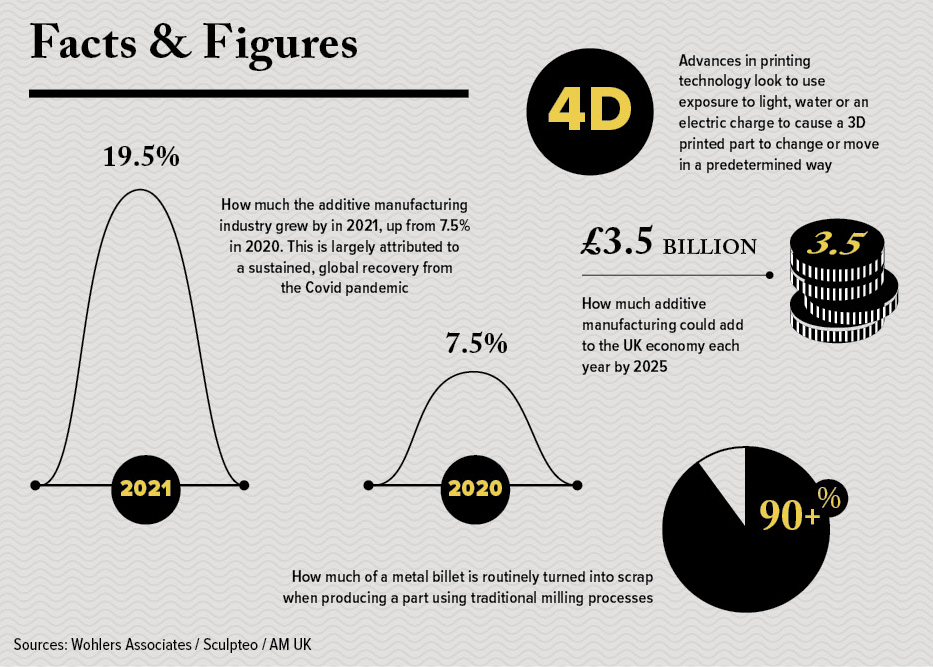

Additive manufacturing remains a fast-developing sector on a global scale, but the UK’s adoption of the technology, backed by sustained R&D and a strong design and engineering sector, has helped gain international recognition.

Aside from the usual suspects that have been around for some while – hearing aids, teeth aligners, prototyping – 3D printing is being further adopted by manufacturers to great effect, but not always in the most direct way.

While the mass manufacturing of everyday items using 3D printing remains some way off, its ability to have a wider impact has seen it craft footholds from where it is set to grow further.

The pandemic and the resulting supply chain disruption has played a role in advancing additive manufacturing, as companies found solutions using some of the most inexpensive equipment and materials at hand.

Factory line parts that were traditionally machined out of metal, not for design or load constraints, but because aluminium and steel were easily available, are now being 3D printed from polymers.

These aren’t always beautiful, high-resolution parts, but custom parts printed fast, often on a sub £5,000 machine. It means an entire factory line can be swapped in a matter of hours. Companies such as L’Oreal used the technology during the pandemic – swapping its cosmetics lines over to things like hand sanitiser faster than previously imaginable.

Matthew Forrester, head of Materials Transformation & Recycling Science at L’Oreal, states that quick wins are the key to speed and educating its workforce to help change mindsets about materials, with huge cost and time savings.

“That’s where additive is really becoming a gamechanger because we can now change our production lines that quickly,” he says.

Non-critical parts can now be quickly and inexpensively 3D printed using ABS-like materials. Tough composite-filled parts can be used for more rigorous use cases, or even materials like BASF Ultrafuse that once printed on a simple desktop machine can be then fired in an oven to produce a solid metal part.

Added innovation

Lightweighting has seen an incredible amount of attention with the rapid rise of electric vehicles prompting automotive companies to further explore additive methodologies. Although current examples in production are mostly limited to high-function parts on low volume luxury marques, given the ramp-up by manufacturers, we’re not far away from more mainstream applications.

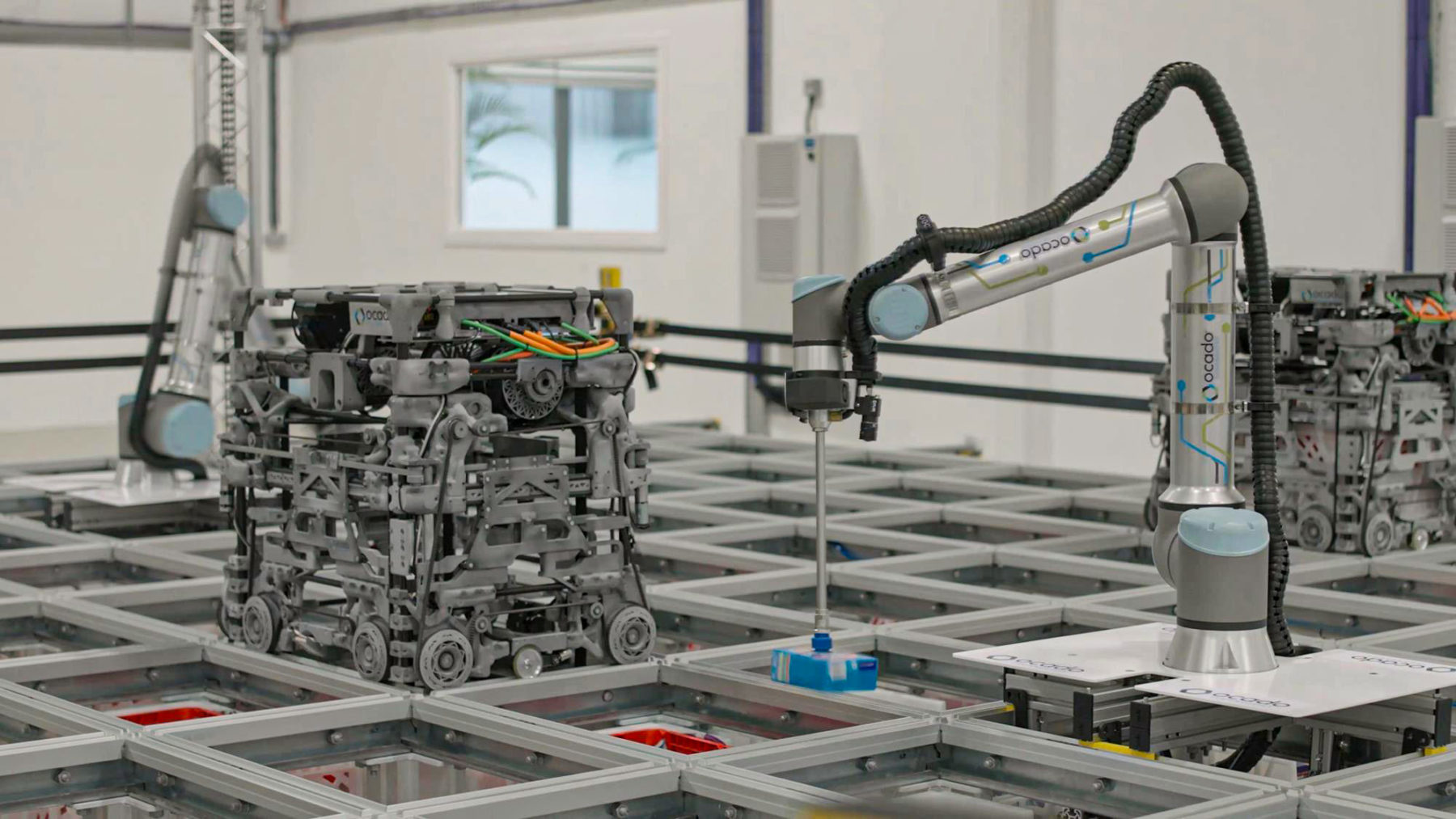

Away from the roads, Ocado Engineering, the technology arm behind the UK online grocery fulfilment company, has used topology optimised design for its latest 600 Series robot, using HP 3D printing to produce more than 300 of its parts. As a result, the robot is five times lighter, significantly faster and more cost-effective to manufacture than previous models.

“Because the 600 Series bots are highly energy-efficient and require a lot less power to achieve the same throughput from the same footprint, new sites will require less chill equipment, lowering energy consumption levels and overall construction costs,” says Ocado CEO Tim Steiner.

The lighter the robots, the easier site planning is, and its technology can be installed more cheaply and simply into a wider variety of buildings, serving more customers and widening the retailer’s reach around the UK and further afield.

With around half of the parts 3D printed gives Ocado the incentive to place 3D printers at each factory location to produce spare parts – another area that’s seeing increased take-up. For many, the beginning of this ‘digital inventory’ profile starts not with the manufacture of a piece of new hardware, but

by analysing existing stock to find parts that can benefit economically from being produced additively.

The likes of Castor have created software to do this, with companies like Maxiom Wheels using it to crawl their database of products and find those they can immediately benefit from 3D printing. Actionable digital inventories are shooting up priority lists thanks to ongoing supply chain disruption, and the introduction of artificial intelligence to combine or redesign parts for additive makes this an exciting advancement.

Additive is already playing a huge role in spare parts, with companies like UK rail leasing agent Angel Trains and providers like Deutsche Bahn and Siemens expanding their use of 3D printing.

“The problem is that traditional manufacturing methods only make it cost-effective to produce high volumes of spare parts, even though an operator may need just a few obsolete train parts replaced. Lead times can also take months, exacerbating the issue even further,” explains James Brown, product manager for decarbonisation at Angel Trains.

Materials such as Stratasys’ ULTEM 9085 have gained certification to meet strict carriage fire and safety guidelines, allowing rail companies to have necessary spare parts in stock on the spot.

Similar use cases can be found for aerospace and defence, with additive manufacturing helping perform life-extending builds for ageing military aircraft; or low volume manufacturing to equip a fleet of helicopters with custom mountings required to install the latest equipment.

A more consumer-focused angle is the growing trend for converting classic cars into electric vehicles. Rare, spare or custom parts are increasing in demand, a trend not only for the roads but those wishing to convert boats and, further down the line, light aircraft to sustainable fuel sources.

The future’s focused

Global semiconductor shortages mean the equipment for producing them is under pressure to increase output. Additive in semiconductor machinery can help with heat dissipation and reduce vibrations by combining multiple components into a single part.

Vendors producing standalone 3D printers are all evolving their ecosystems to be as relevant in as many verticals as possible, but a new breed is emerging. The near future sees more companies adding targeted turnkey solutions for specific industries and products.

Start-ups like Holo AM are focused on working with manufacturers to add performance and value to thermal management products. Right now, it combines copper 3D printing technology with geometric design freedom, underpinned by traditional high-volume metal injection moulding post-processing, to produce liquid cooling solutions be they high power semiconductor devices like GPUs or inverters for EVs.

This example is a growing one for many 3D printer vendors as they look to create a very specific solution to fit a hole in a manufacturing value chain.

3D printing ecosystems and solutions are evolving into new spaces and finding very profitable niches. A revert to ‘normality’ is unlikely to see this progress slow. l

News in Brief

- Founded by automotive design royalty, Sir Ian Callum, his eponymous new design house Callum Design uses 3D printing to produce parts for the modern reworking of his Aston Martin Vanquish

- Edinburgh-based Choose Packaging specialises in the development of paper-based alternatives to plastic bottles. The company was acquired by HP in 2022 and uses its 3D printing-enabled Molded Fiber Tooling

- JT Custom Adaptive is using 3D printing to design bespoke handgrips and parts for para-athletes at a lower price point than traditionally possible. Already shipping worldwide from its Eastbourne base, it hopes to expand its offering to reach anyone in need of custom equipment

- Welsh industrial designer Ross Lovegrove created an exoskeleton for a perfume bottle inspired by the cockpit cocooning a driver in an F1 racing car. The exclusive casing was built not in Monaco, but Darlington by Paragon Rapid Technologies using Carbon’s DLP resin technology

- Alvis Car Company is playing a part in rescuing dying manufacturing skills by using 3D printing and scanning to help make the moulds, or ‘bucks’, over which traditional panel beaters hand sculpt aluminium car body panels – saving time and costs and resurrecting the classic British marque

- Bishop’s Stortford’s Lamp & Pencil built bespoke stage lighting using desktop Formlabs 3D printers to help get West End productions back up and running when traditional suppliers struggled post-pandemic

“Supply chain disruption has played a role in advancing additive manufacturing”

Above: Callum Design is using a desktop 3D printer to rework and modernise the interior of its Aston Martin Vanquish. Credit: Callum Design

“Additive is already playing a huge role in spare parts”

Above: Luxury goods are being elevated through 3D printed packaging, like this F1 fragrance. Credit: Paragon Rapid Technologies

Above and below: Lamp & Pencil printed 100 lenses in Formlabs Clear Resin to cover the front of each LED. This blended with the rest of the set and concealed the LEDs, without affecting the light output. Credit: Both Lamp & Pencil